Description

Hydraulic Press Brake for metal bending

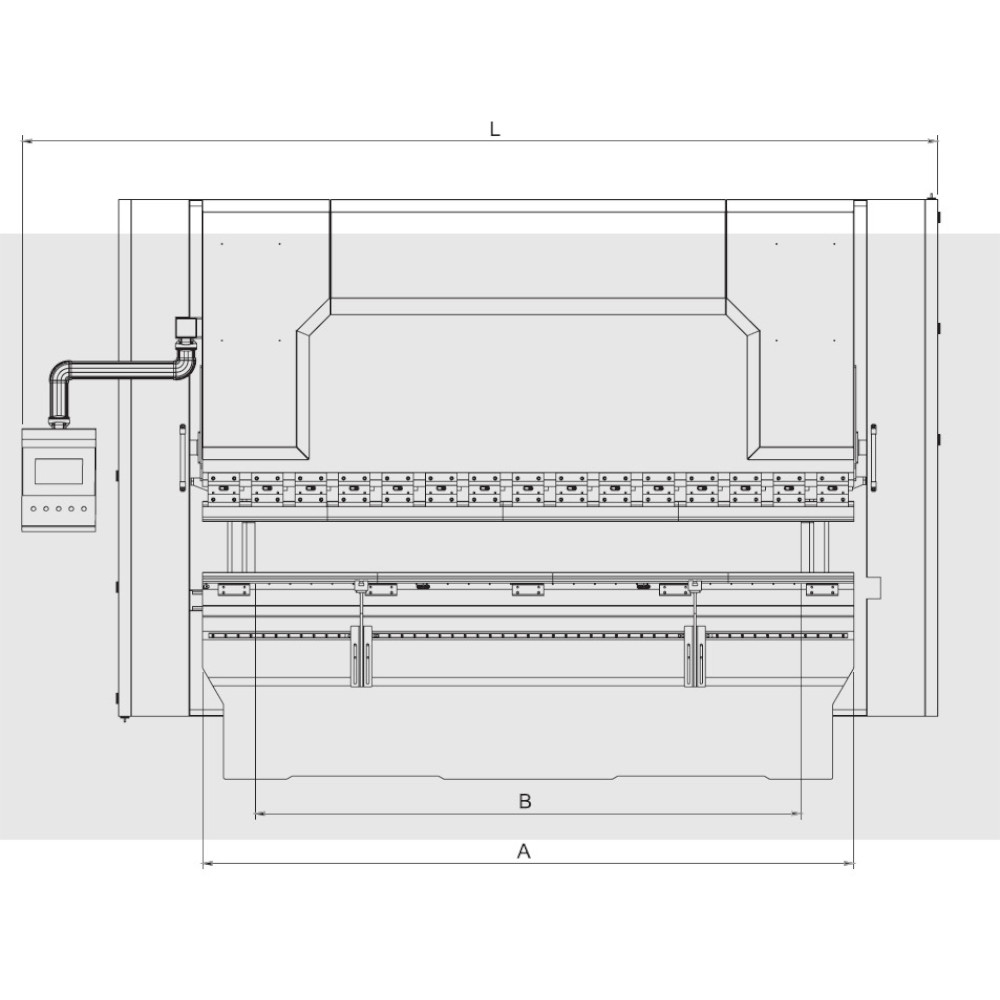

Hydraulic Press brake provide high-quality bending in a wide variety of materials and different thicknesses. Press brake has from 44 tons to 350 US tons of bending force. The machine automatically performs the bending angle, bending distance, bending length, and bending shape by entering the material type, thickness, and length and bending points into the control unit or by loading the technical drawing of the part to be bent in the control units with 2D graphics and 3D graphics features. The precise movement of the upper table is provided by linear rulers which helps to lessen the skid lubrication and maintenance much.

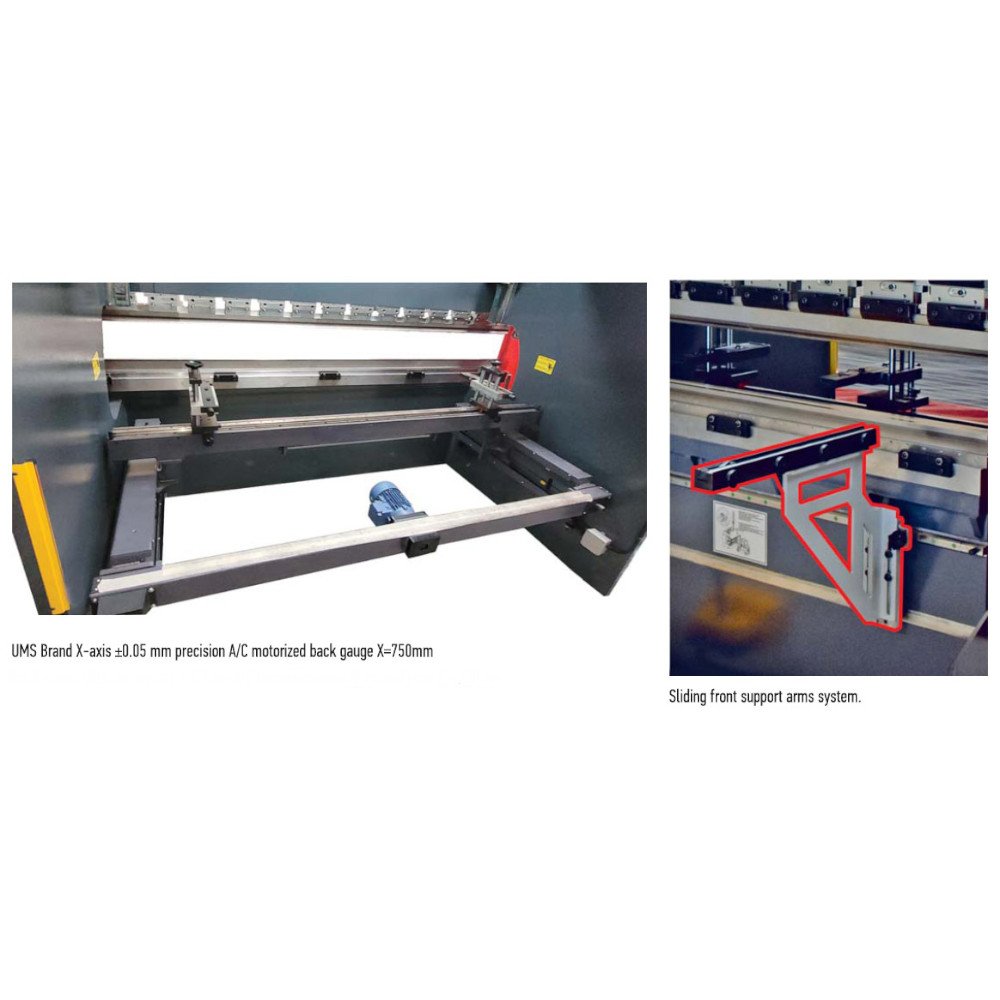

It can also be produced for high thickness and big bending length capacities. Press Brakes back gauge with X movement 29 1/2″ inches, 750 mm and ball bearing shaft and gap less sliding. The back gauge has a programmable positioning accuracy of +/-1/64″ inch according to the shape of the products to be bent.

See all our Press Brakes

Key Features

Y1, Y2, X, 3 Axis CNC

CYBELEC TOUCH 8 (Switzerland) B” CNC Control Unit

10 1/4″ inch, 260 mm Stroke, 16 1/8″ inch, 410 mm Throat Depth

Höerbiger (Germany) Hydraulic block with proportional valve

Eckerle (Germany) oil pump, intemal gear type.

GIVI (taly) Magnetic Linear Rulers

UMS Brand X axis +1/64″ inch precision

A/C Motorized back Gauge X = 29 1/2″ inches, 750 mm

2 backgauge fringers can be moved manually along the linear guide,

precisely adjusted.

Side doors for safety and cylinder covers.

Promecam (European type) quick Connection system

Sliding front support arms system 2 Pcs

Tight Base Table from UMS IW= 2 3/8″ inch (F<=22Ton) IW= 3 1/2″ inches (F>=295 Ton)

EUROSTAMP (taly) standard upper punch tool 1260,

H:67,85″ R:08 (32 7/8″ inches x length+ 1x 31 3/4″ inches piece set)

EUROSTAMP (Italy) standard bottom punch tool 2067,4-channel

V-5/8″-13/16″-1 3/8″-2″ inches 85° H:60 (32 7/8″ inches x length+ 1x 31 3/4″ inches piece set)

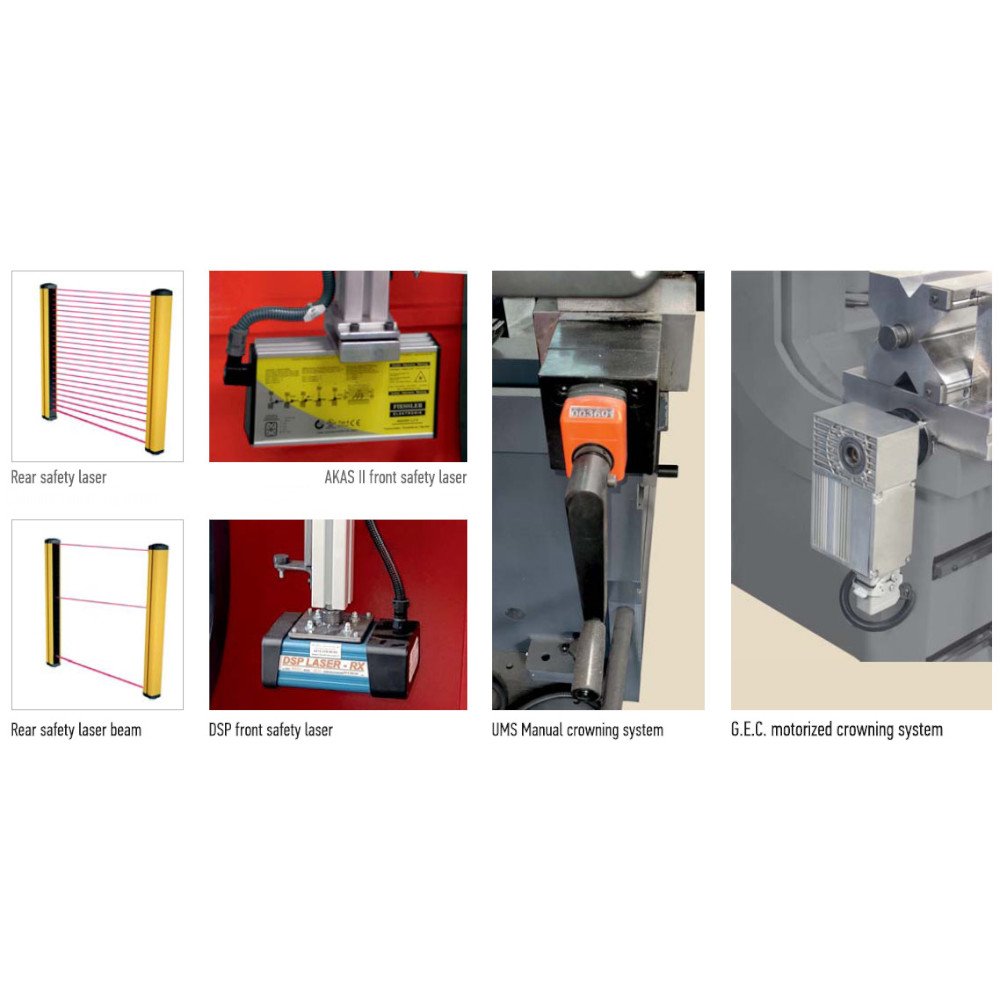

Laser lights front and rear safety system

Led illumination

Optional Features

4-6-8 Axis back gauge options starting from X

Large base table for multi-channel punch tools

UMS manual crowning system

6.E.C. motorized crowning system

Back gauge with x distance 39 3/8″ inches, 1 meter

Akas or Dsp laser light barrier system in front and back.

Additional back gauge fingers