Description

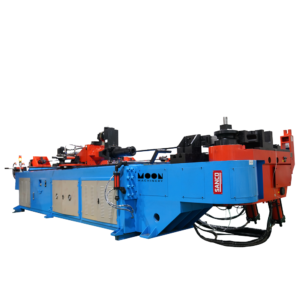

Introducing the fully automatic pipe bending machine, a cutting-edge solution for precision bending. This machine features electric bending, feeding, and rotating capabilities, while hydraulic options are available for bending and clamping processes, providing enhanced flexibility.

User-friendly operation is ensured with a touch screen interface supporting multiple language options, including English. The PLC controller guarantees smooth performance, with the option to upgrade to a Windows XP Industry PC for advanced functionality.

For temperature control, you can select from fan, water, or oil cooling systems based on your specific requirements. Additionally, the machine comes with an auto lubrication function for consistent performance and reduced maintenance needs.

Reliability is guaranteed through the integration of top-quality electric and hydraulic components sourced from Japan, France, and Germany. Furthermore, this machine boasts Taiwan’s core technology, which has been continuously refined since 1989, ensuring unmatched expertise and reliability in pipe bending.

Here is a link for all our CNC Pipe Bending Machines;

https://moonmachineryinc.com/product-category/metalworking/metal-fabrication-machinery/pipe-bending-machines/cnc-pipe-bending-machines/

Optional Features

Bending Capabilities:

- DR (Double Radius): Allows for double radius bends, expanding design possibilities.

- TR (Triple Radius): Enables triple radius bends, ideal for intricate tube configurations.

- QR (Quadruple Radius): Offers quadruple radius bends for advanced and complex designs.

- MR (Multi Radius): Provides the capability for multi-radius bends, catering to diverse applications.

- LR (Left and Right Direction Bending): Allows bending in both left and right directions for versatile tube formations.

- R (Rolling / Pushing): Supports rolling or pushing bending techniques for specialized tube shaping.

- P (Punching): Equipped to perform punching operations on tubes, adding holes or indentations.

- C (Cutting): Provides cutting functionality to trim tubes to desired lengths or shapes.

Enhanced Performance and Safety:

- Safety Cover: Includes a protective cover for improved operator safety during operation.

- Bend 1.0XD Radius, or More Tight Radius: Enables precise bends with a 1.0XD radius or tighter for intricate designs.

- Auto Mandrel Lubrication System: Features an automatic mandrel lubrication system for consistent performance and longevity.

Temperature Control Options:

- Fan / Water / Oil Cooling System: Offers a choice of cooling methods to regulate machine temperatures for optimal performance.

Automation and Control:

- Robot Loading and Unloading: Allows integration with robotic systems for automated tube handling, enhancing efficiency.

- Windows XP Controller: Provides a user-friendly interface through a Windows XP-based controller for seamless operation.

- Industry PC (3D Tube Showing, Function of Mirror Image, and Reverted Image): Offers an industry-grade PC with advanced features like 3D tube visualization, mirror image, and reverted image functions.

- 3D Bending Simulation, Can Read CAD Files: Allows 3D bending simulation and the ability to import CAD files for accurate pre-visualization of bending processes.

Precision and Measurement:

- Connect Three Coordinates Measuring Instrument: Enables connection with three-coordinate measuring instruments for precise measurement and quality assurance.

Safety Devices:

- Safe Blanket / Infrared Alarm Device: Equipped with a safe blanket or infrared alarm device to ensure operator safety and prevent accidents.