Description

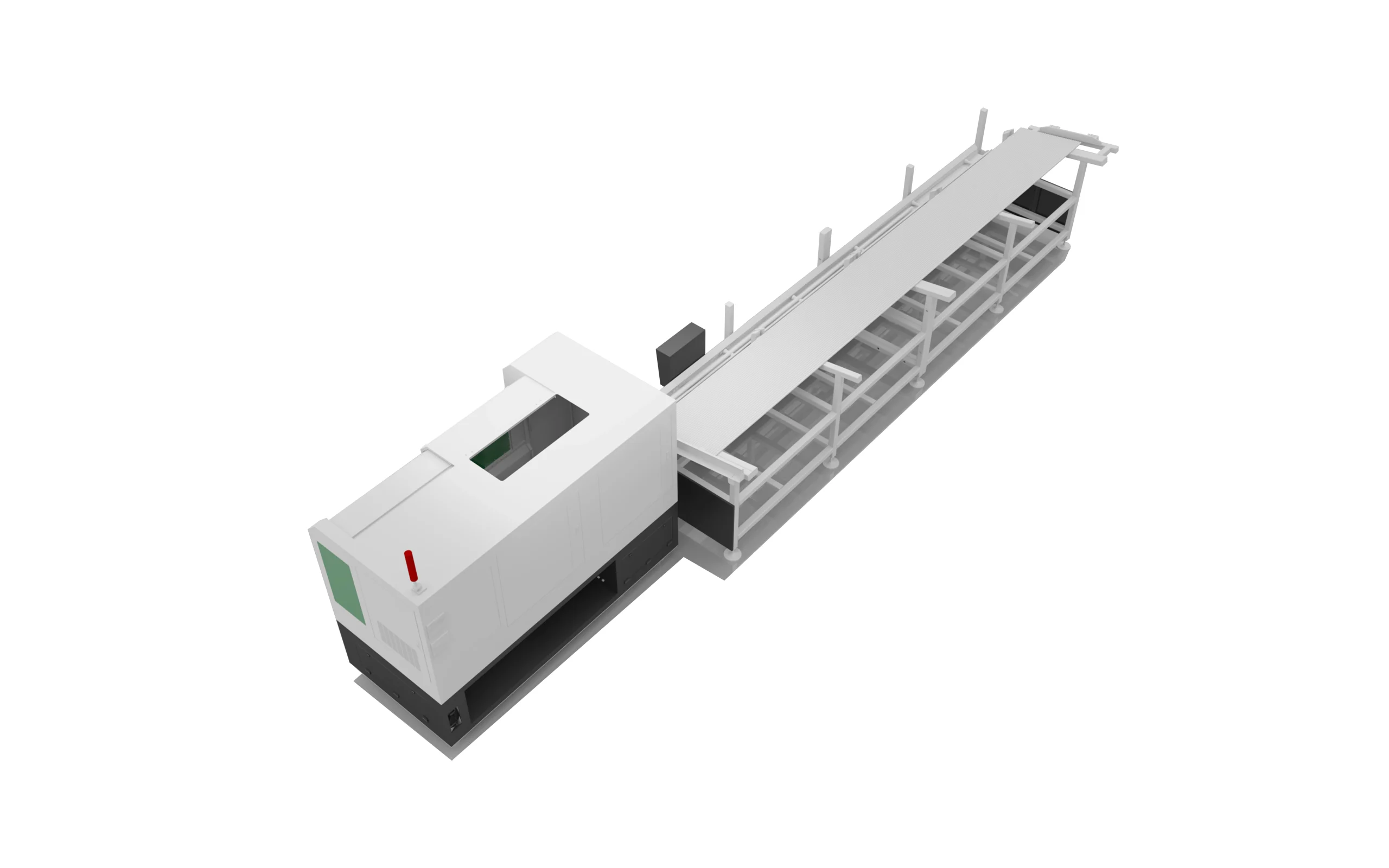

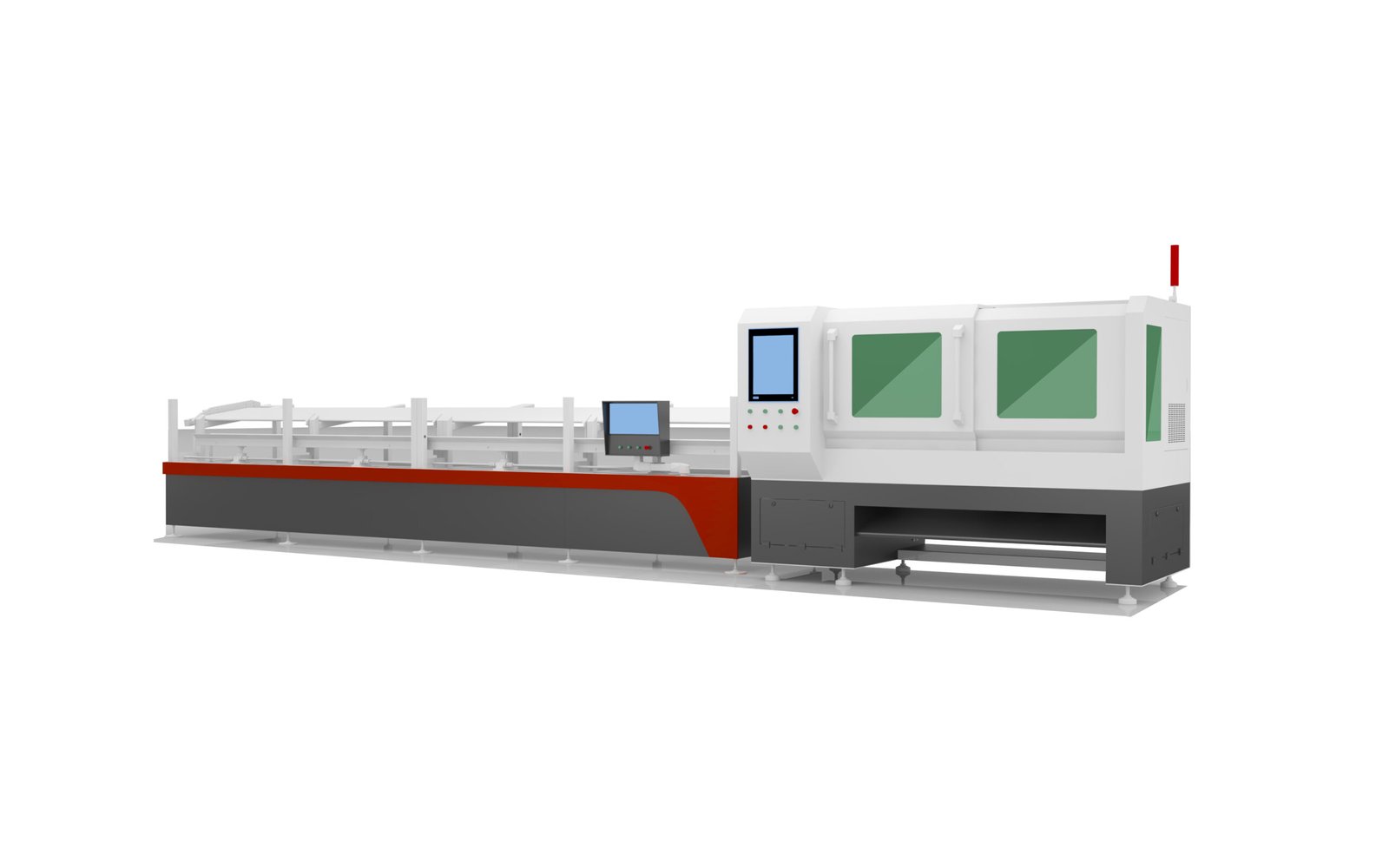

Tubex fiber laser tube cutting machine gives the fabricators what they needed in terms of flexibly, ability and 3 more axis,

Now Our tube cutting machine is available on 5 axis for when additional power and flexibility needed.

Fully close enclosure is being sure that fiber laser cutting machines matches with CSA safety standard but e-safe .

Machine already comes with a 3d software system that allows operators to priories the process and see all need to be done on a 3D preview mode.

|

Processing Format & Working Range |

|

|

Pipe Processing Range |

236″ x φ13/32″- 8 21/32 □13/32″-5 28/32″ |

|

X-axis Stroke |

11 13/16″ |

|

Y-axis Stroke |

255 29/32″ |

|

Z-axis Stroke |

11 13/16″ |

|

Accuracy |

|

|

X/Y Axis Positioning Accuracy |

± 1/64″ /m |

|

X/Y Axis Repositioning Accuracy |

±0.03m/m |

|

Speed |

|

|

Max. Moving Speed Y axis |

109 yard/min |

|

Max. Chuck Speed |

100 r/min |

|

Weight & Size |

|

|

Max Single Tube Loading Weight |

3373 lbs |

|

Shortest Tail Length |

5 7/64″ |

|

Dimension(L×W×H) |

381*81.88″*x 106.29″ |

|

Weight(kg) |

10667 lbs |

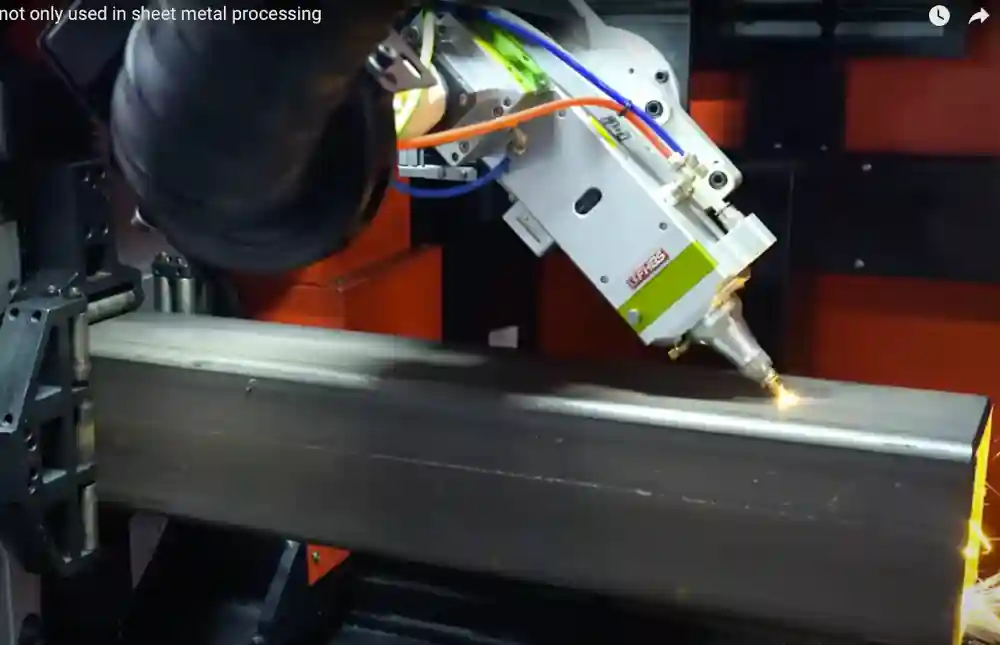

Five axis fiber laser advantages for profile and pipe cutting

Front Chuck: An aluminum cover is utilized to enhance the chuck’s corrosion resistance and sealing performance, while a full-stroke external roller is implemented to improve the chuck’s clamping force and load-bearing capacity. Additionally, the chuck is equipped with a pressure-holding feature that can sustain pressure for up to 8 hours, preventing any potential safety hazards resulting from unexpected power or gas outages.

Rear Chuck: The installation of the product can be easily done using keyway positioning and requires no comb adjustment. The front chuck can extend the rear claw to achieve ultra-short tail cutting. With robust rear clamping force and an anti-skid claw, the pipe remains secure, minimizing the risk of slipping or falling off.

Servo driver profile following support system: The product employs an up and down following movement mode, which significantly enhances the cutting accuracy and load-bearing capacity by providing efficient support for the pipe.

Cutting Head: The bevel cutting head can rotate ±45°, and is crafted from aviation-grade aluminum material with high-precision machining, ensuring exceptional rigidity for improved accuracy and cutting stability. This design enables the product to cater to a wider range of application scenarios, meeting even the most stringent welding requirements.

Almost all materials common in the metal processing industry, steel, aluminum, carbon steel, mild steel, galvanized sheet, steel coil, zinc coated steel sheet, brass, stainless steel, electrolytic plate, alloy, and other ferrous and non-ferrous metals can be fatly and accurately cut by the laser cutting machine.

Click here to see all fiber laser cutting machines.

tube laser cutting machine, fiber laser cutting machine, sheet metal cutting machine, toronto, canada, moon machinery,G Series, fhbs laser, chinise machine, chinise mfiber laser sale, laser price, 5 axis laser machine price