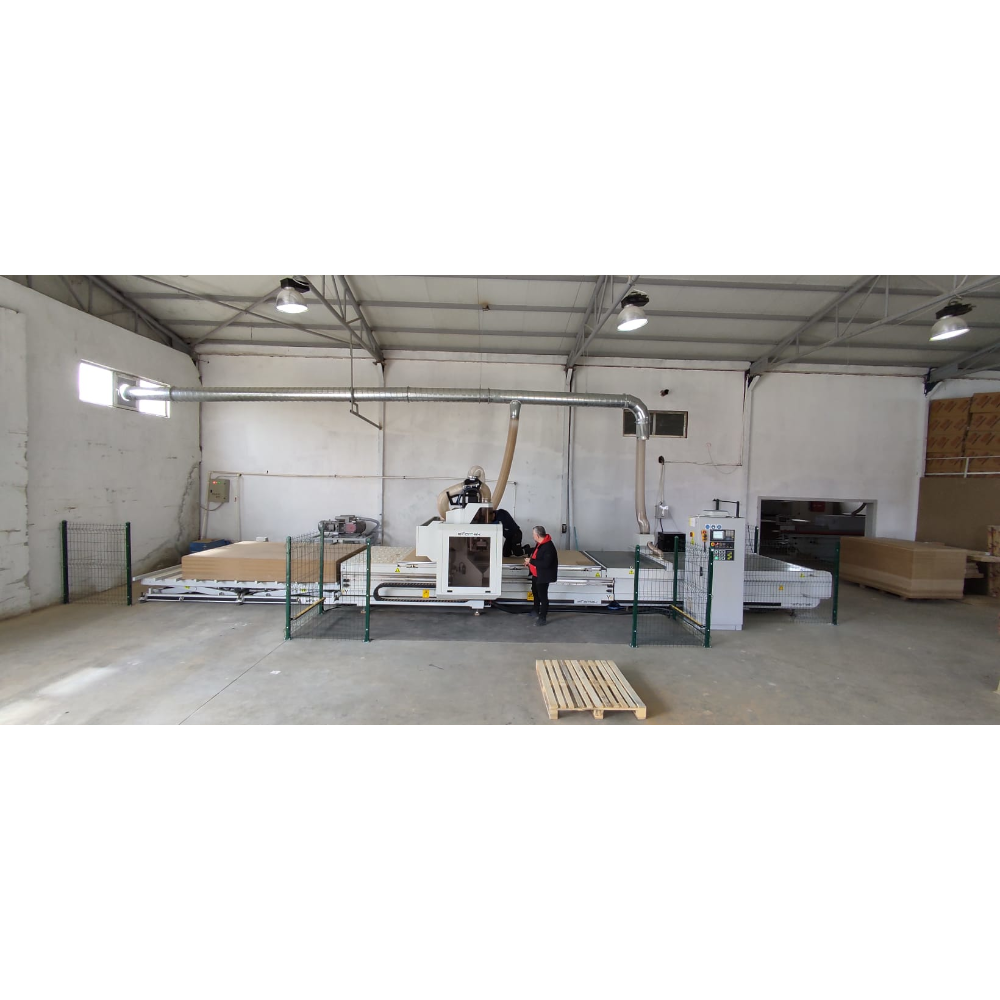

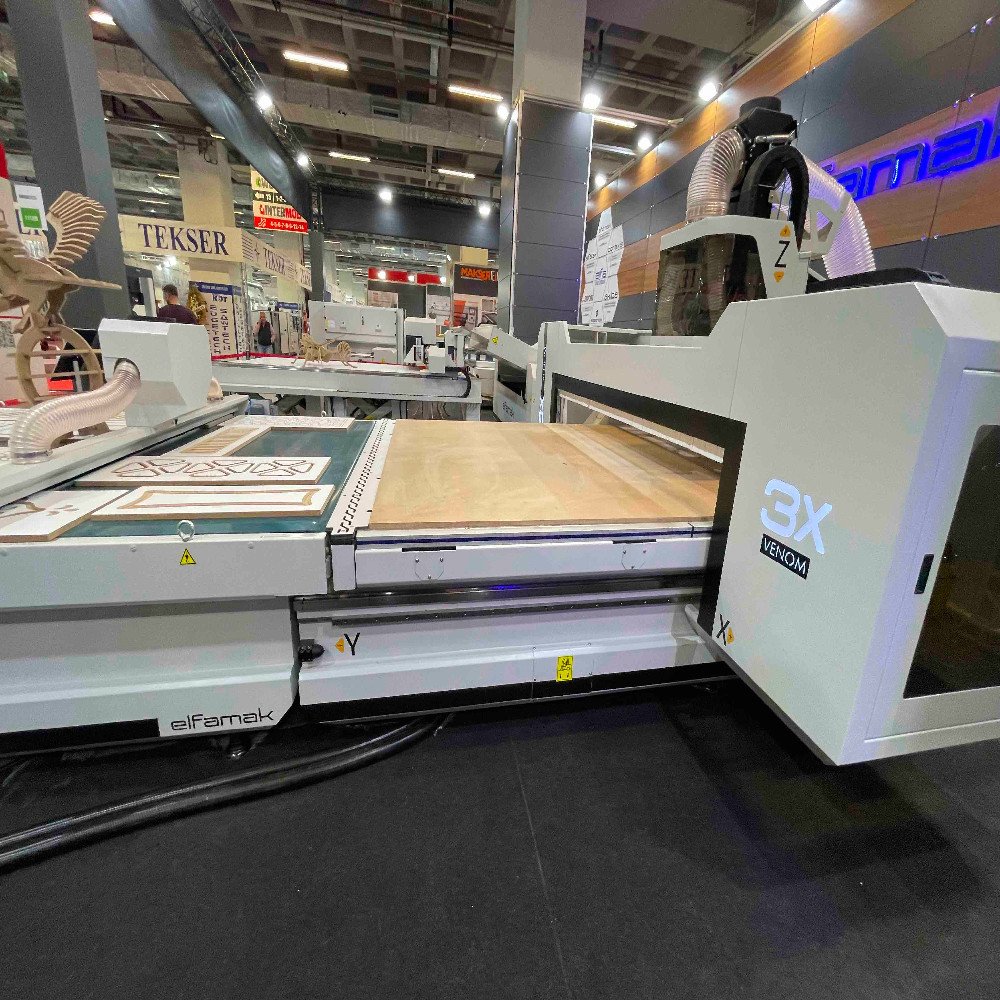

Description

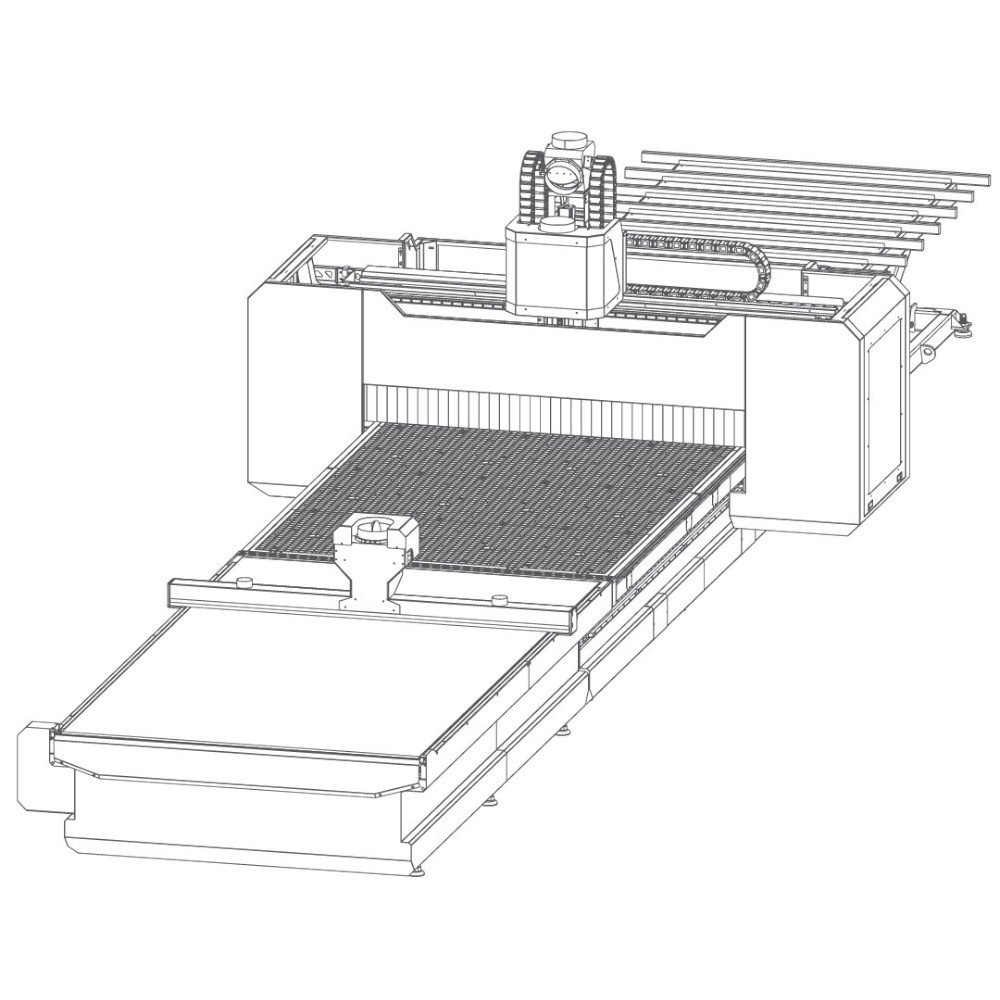

In the CNC Machining Center guide rail and helical roacks of our machines are produced as monoblock in double colon CNC. Thanks to this chassis structure of our machines cleansed from vibration. We created a strong construction, which stands up to high performance for a long time and we keep parallelism of helical rack and guide rail with minimum tolerance gop. In this structure all surface of helical racks and even bottom gears are grinding. This provides best results at maximum speed.

Lasting Guides and Rails

Automated lubrication system ensures the continuous lubrication of the machine’s main moving parts without the need for operator intervention. Central System Automatic Timer Dosage Adjusted (To be able to lubricate every point with required amount).

32 Set Rotary Tool changer

In CNC Machining Center series we use mobile automatic rotary tool with 32 tools, which are compatible with automatic loading and unloading system. Machine automatically changes all tool kits in automatic mode. Moreover, user independent system automatically measures kit’s length, saves it to memory and continue process using this measurement. If required, additively kit changing process can be done by operator manually.

HSK F63 Spindle

In our machines we use HSK F63 type, 11 kW air cooling spindle motors. This enables our machine can mill different kind of materials comfort ably such as: woods, plastics, plexiglasses, alucobands, aluminiums and soft metals. Also, we use best quality German ceramic bearings in our spindle motors. Amazing precision 0.2mm accuracy on engraving, 0.001 mm programming precision , 0.05mm repeatability response. Outstanding precision supplies a good finish on your door processings.

Only ELFAMAK has this user-friendly technology provided in Canada by Moon machinery inc. Even if the program made by operator in the system is mistaken, spindle motor stops working at 1/16″ distance to work table. With the help of this smart software, which put into service with CNC Machining Center and your work table and spindle motor are not damaged.

Industrial Grade Aluminum Table

8 zone controller aluminum plate. CNC machining center can process Aluminum panel, composite panels, laminate, plexiglasses, alucobands, mdf , ceramic, fiber concrete panels . CNC machining center provide high capacity machining speed with automatic loading and unloading station for cabinet manufacturers, kitchen manufacturers, store fixture companies, window and door manufacturers, cladding companies.

Servo control System

Servomotors, servo drivers, control units and cable groups in all movement axes are Beckhoff brands. It enables smooth operation of the machine at high speeds with its full compatbility and the highly secure communication protocol.

Boring Unit

14 vertical 3×2 horizontal and one saw boring unit can be add to CNC machining center as optional. different configuration can be customized as per customer requirement.

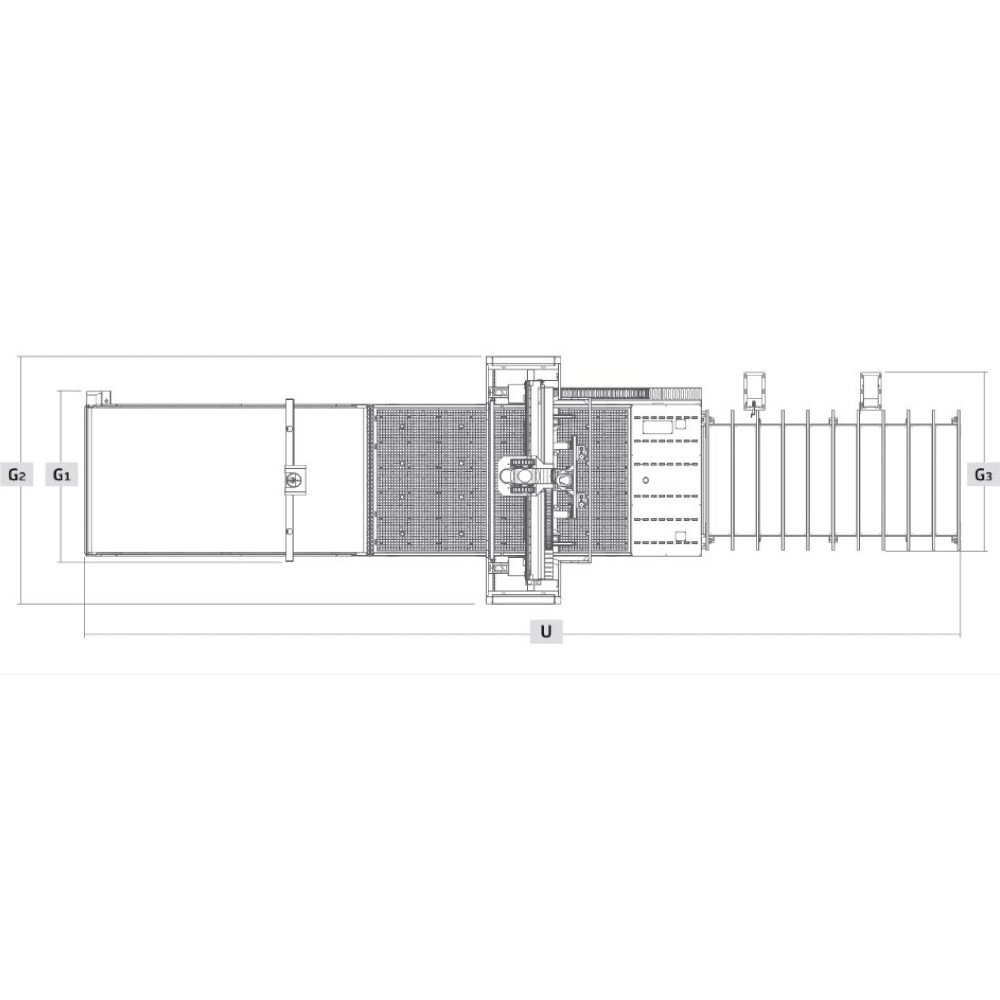

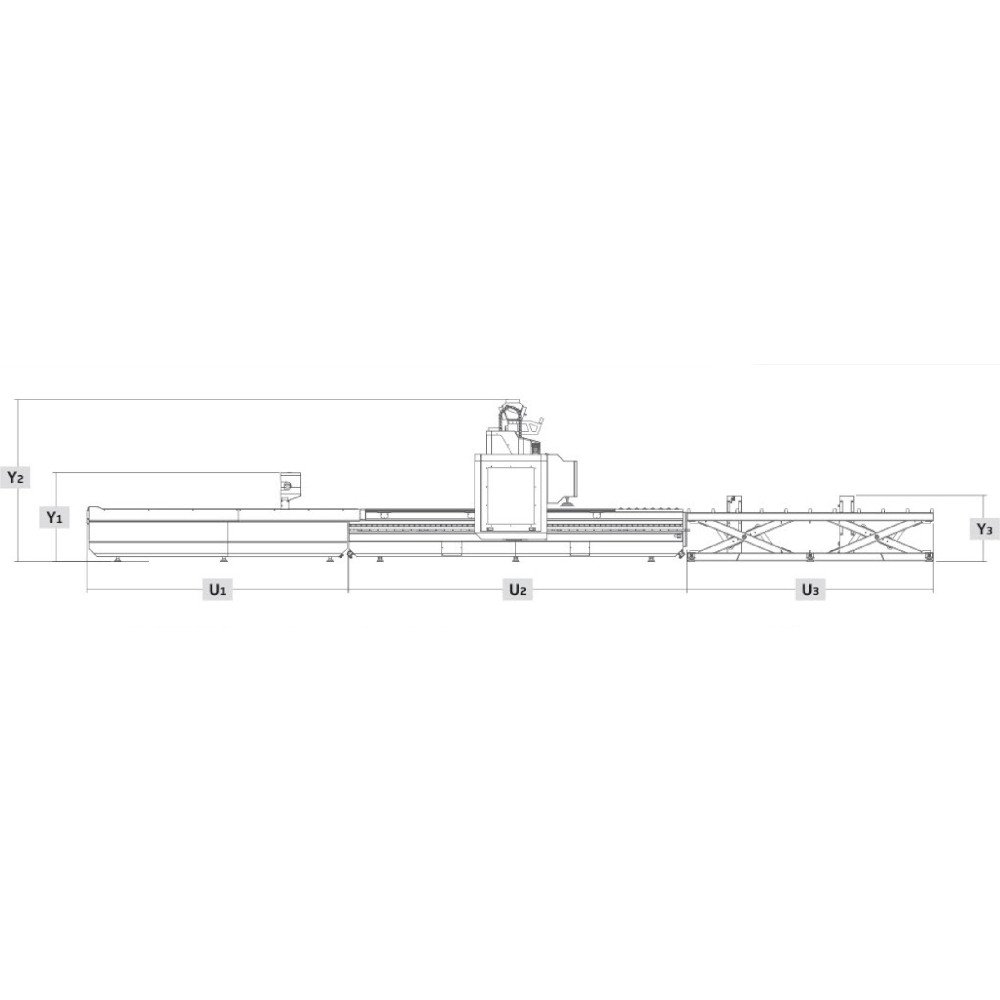

It is the front conveyor of the machine where the cut parts are carried by the unload- ing and sweeping system. The fact that the discharge conveyor has a sensor allows the conveyor to move as the front parts are taken and all parts to be collected from the front. We can build your next CNC machining center for your specific needs. Free estimate on any engineering needs.

Flat Table Nesting Machining

Nesting table can be order in custom sizes, as default 4 by 8′ , 4by 10′, 5 by 10′, 5 by 12′, 5 by 14′ , 5 by 18′ table can be supply.

Easy usage with our other CNC Machine.

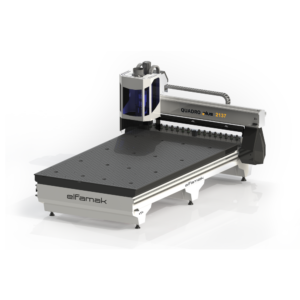

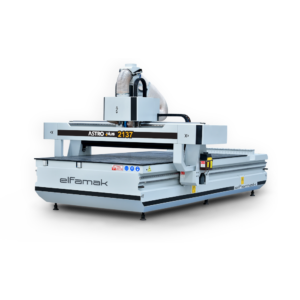

venom 3x, elfamak cnc routers are the great alternative of the homage, biessse or their Japanese competition stiles. Most fabricator chooses the local supplier and Turkish brand CNC machining center as they are getting very similar result at the end of a 8 hours shift. . Then cabinet manufacturers says ” why pay more for the same performance”.