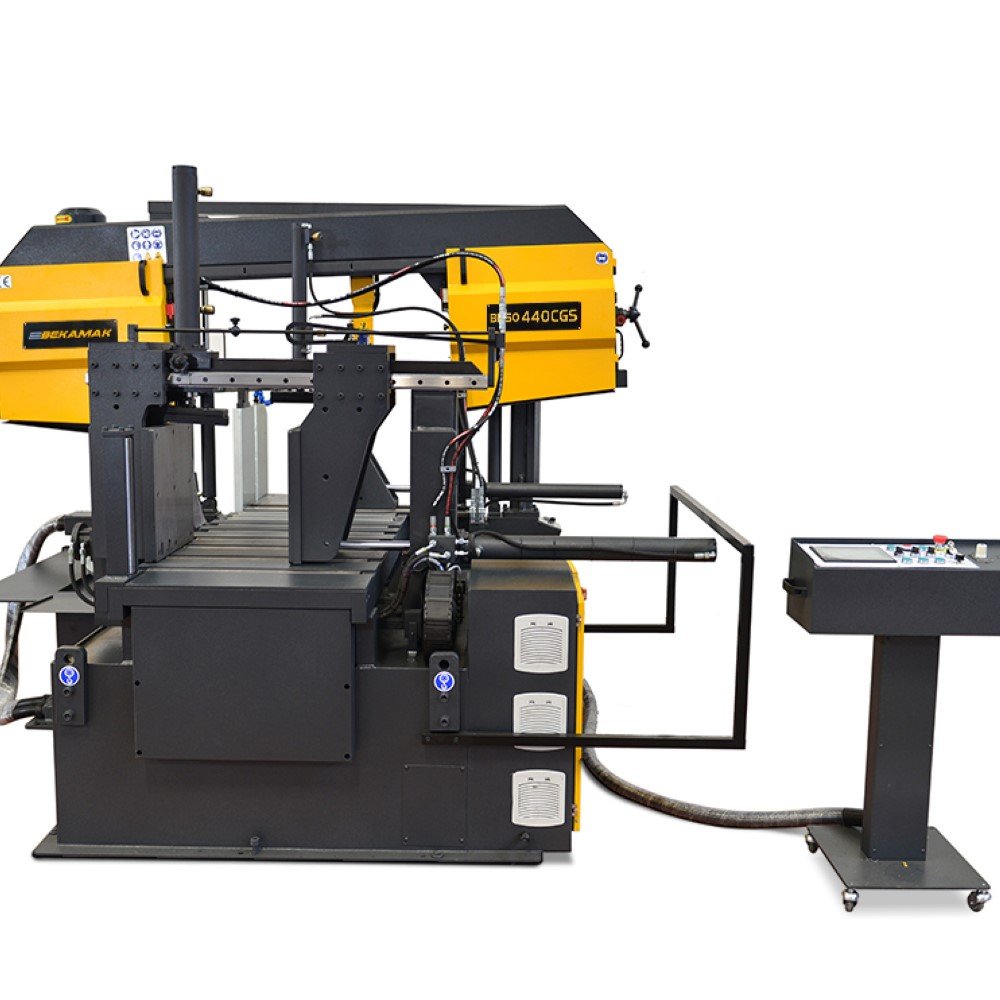

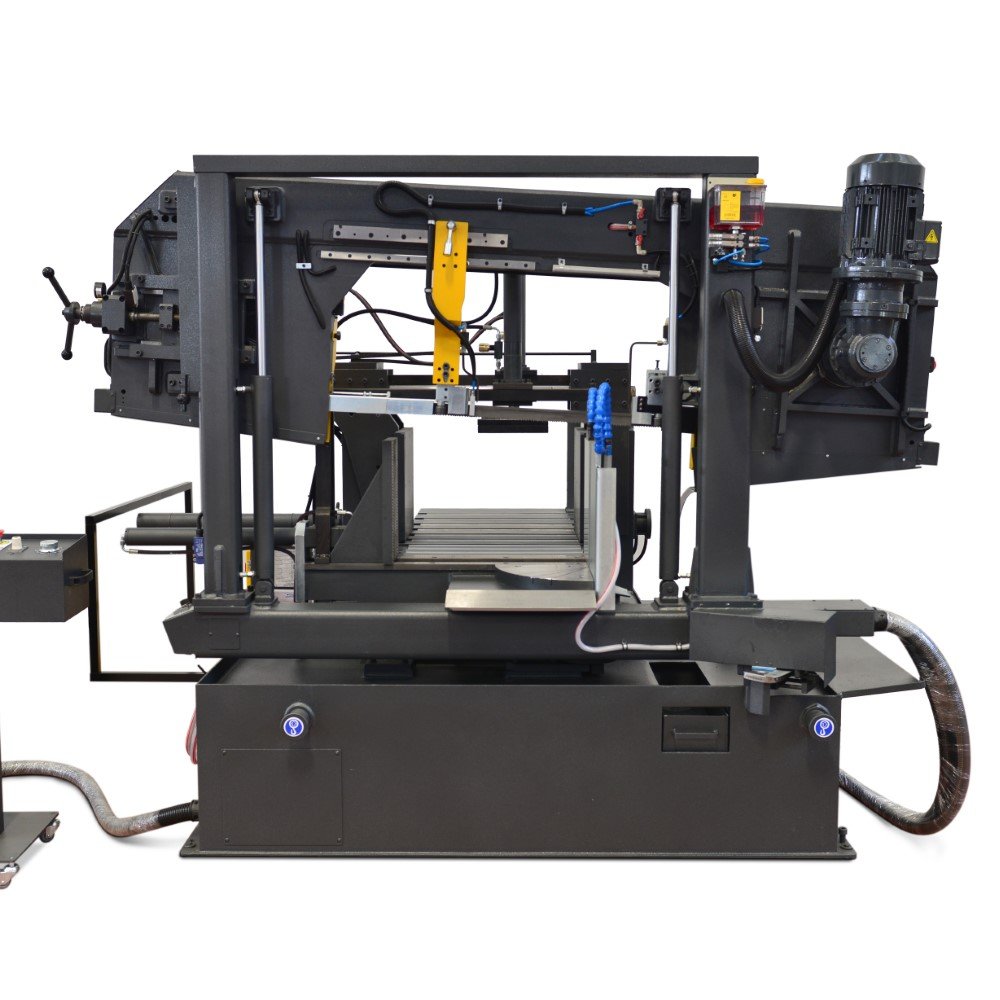

Description

The Fully Automatic CGH Mitre Twin Pillar Saw BMSO-440CGS NC is a high-precision, servo-driven band saw built for mass production and bundle cutting of solid materials, tubes, and profiles. With fully automatic operation and advanced control systems, this model is a standout solution for companies requiring high throughput, repeatable accuracy, and versatility in angular cuts. It is engineered for angular cutting between 0 and 60 degrees, making it suitable for a wide range of applications in structural steel and industrial fabrication.

The Fully Automatic CGH Mitre Twin Pillar Saw BMSO-440CGS NC is powered by a servo-feeding system with a ball screw mechanism, designed to reduce cutting tolerances to virtually zero–a critical factor in high-precision environments. Its integration of Omron’s user-friendly, colour touchscreen PLC control panel enables operators to store up to 30 cutting programs, each with 50 individual steps. This feature allows for highly flexible, pre-programmed cutting routines that save time and reduce setup errors.

Included as standard are hydraulic top clamping and hexagonal vices, ideal for stabilizing material bundles during cutting. The Fully Automatic CGH Mitre Twin Pillar Saw BMSO-440CGS NC also features a comprehensive default equipment package, including an inverter, sensitive pressure adjustment, a digital control panel, and a high-performance coolant pump. This band saw proudly took its place at the EMO 2022 Metalworking Show, affirming its role as a flagship machine in modern metal cutting technology.

With premium performance and smart automation, the Fully Automatic CGH Mitre Twin Pillar Saw BMSO-440CGS NC is a top-tier choice for precision-focused metal processing operations.

Click here to see all twin pillar saws.