Description

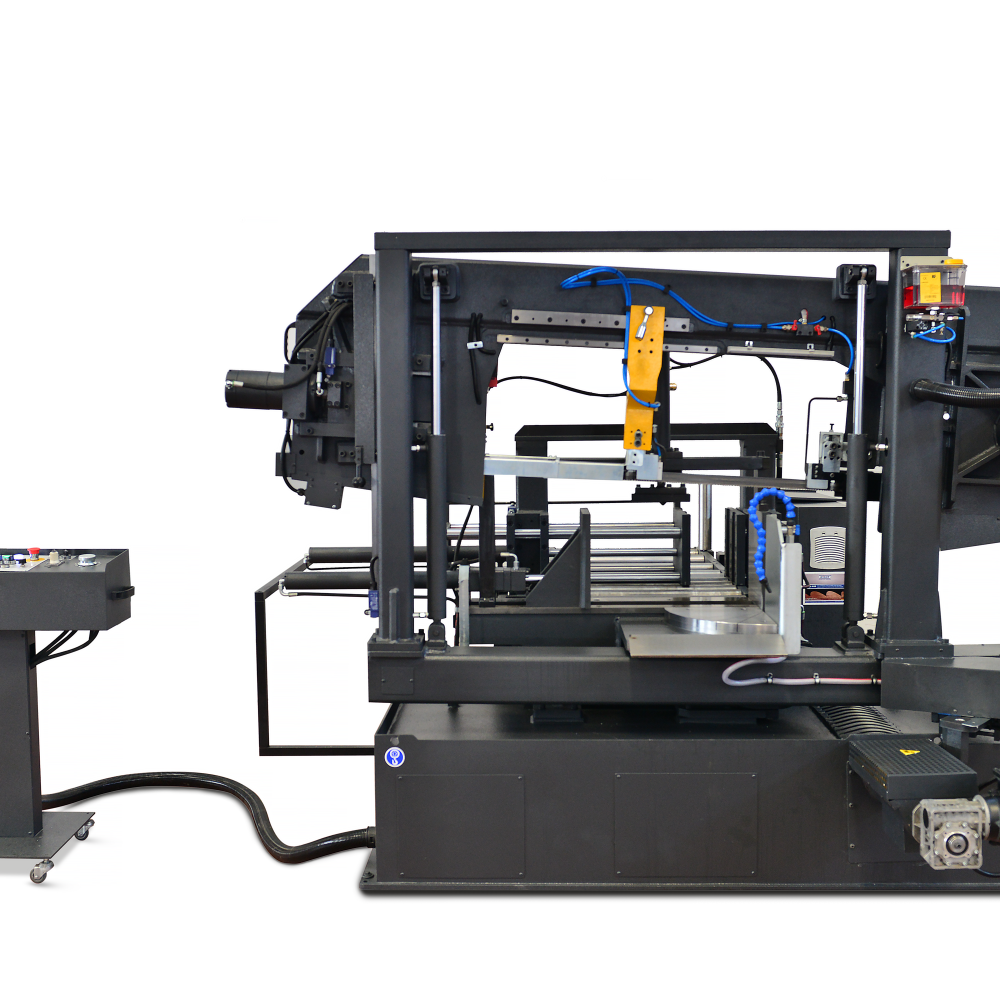

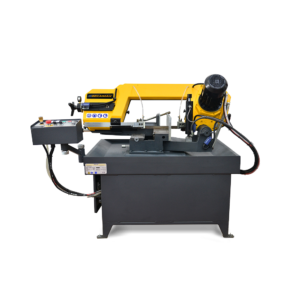

The Fully Automatic CGH Mitre Twin Pillar Saw BMSO-360CGH NC is a fully automatic, PLC-controlled horizontal band saw built for precision mitre cutting in high-volume industrial environments. Engineered with linear guide ways and a column-type structure, this model is ideal for cutting various materials–including solid stocks, profiles, and tubes–at fixed or variable angles.

With the ability to perform mitre cuts from 30 to 90 degrees, the Fully Automatic CGH Mitre Twin Pillar Saw BMSO-360CGH NC supports up to 10 programmable sequences, each adjustable by length and quantity through a user-friendly digital panel. Measurements are completed by repeating strokes based on a 19 11/16″ (500mm) stroke length. At a 90-degree cutting angle, the machine handles flat materials up to 14 3/16″ x 25 3/16″ and round materials up to 14 3/16″ in diameter.

This model includes advanced automation features, such as auto-height sensors that allow the bow to rapidly approach the material, then lift hydraulically after each cut. A mechanical switch manages the cutting process with precision, while a hydraulic brake system, locks the bow securely at any desired angle. A secondary digital counter mounted on the machine body provides intuitive angle control.

The Fully Automatic CGH Mitre Twin Pillar Saw BMSO-360CGH NC places a strong emphasis on safety, as seen across all Bekamak machines. All mechanical and electrical components are configured to meet stringent safety standards, ensuring secure, long-lasting performance.

Whether you’re cutting batches or varying lengths at angles, the Fully Automatic CGH Mitre Twin Pillar Saw BMSO-360CGH NC offers the flexibility and control demanded by professional metal processing operations.

Click here to see all twin pillar saws.