Description

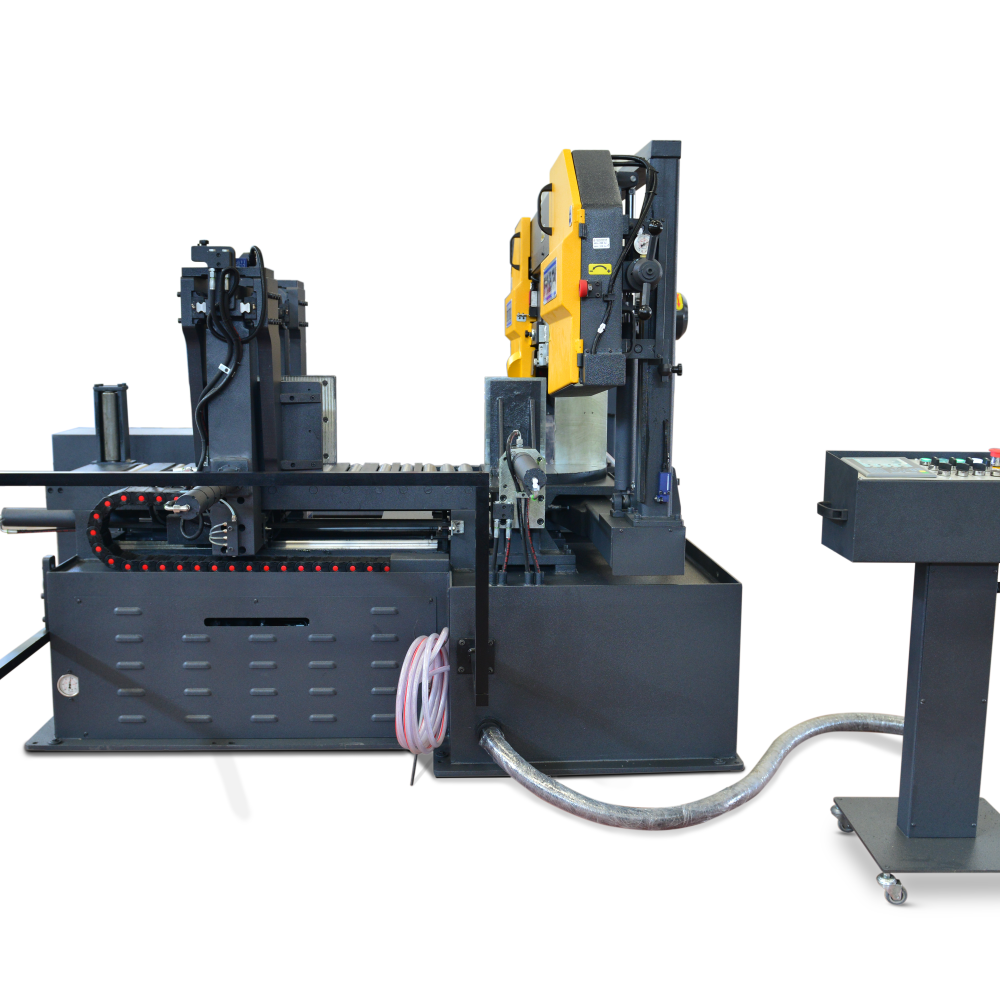

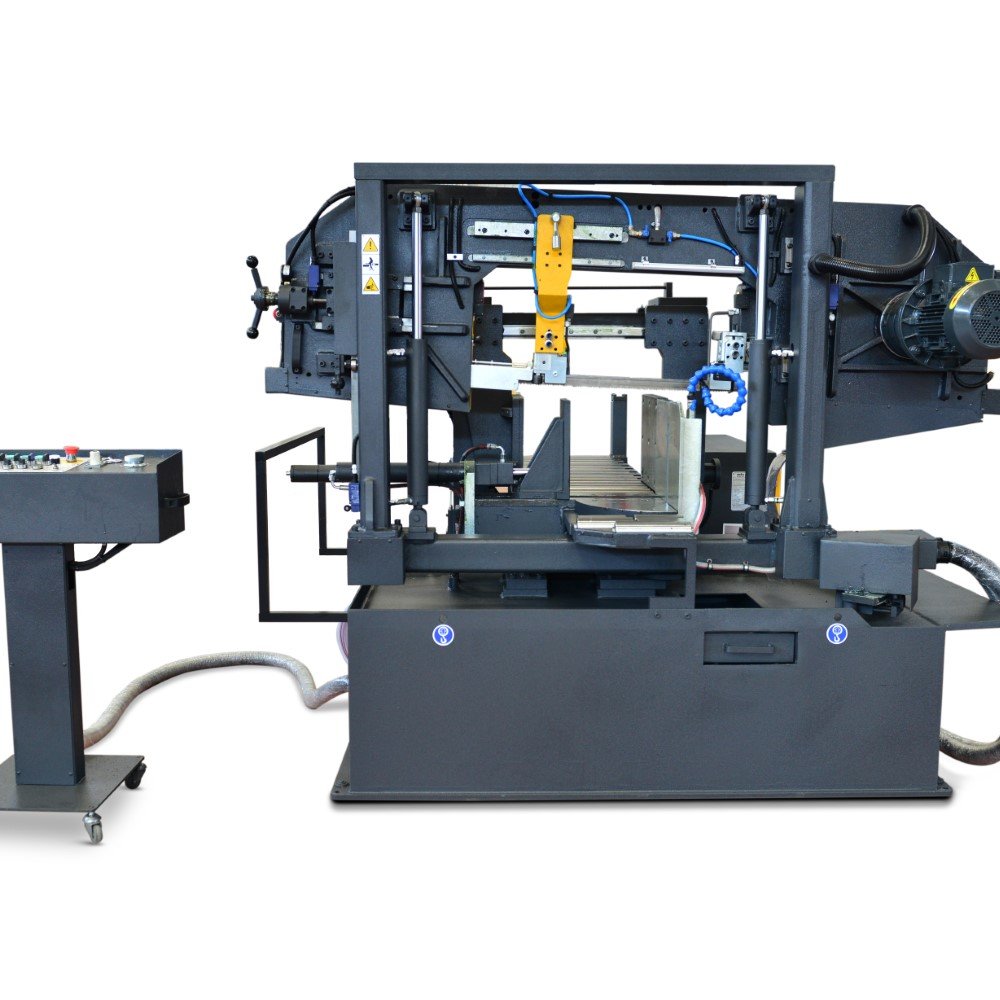

The Fully Automatic CGH Mitre Twin Pillar Saw BMSO-325CGH NC is a precision-engineered horizontal band saw with linear guide ways, designed specifically for mitre cuts in varying quantities. This high-performance model is ideal for operations demanding programmable cutting versatility and industrial-grade reliability.

Thanks to its hydraulic bow movement, the Fully Automatic CGH Mitre Twin Pillar Saw BMSO-325CGH NC enables cutting at angles ranging from 30 to 90 degrees. Operators can program up to 10 different cutting sequences (length and quantity), all visible on the digital control panel. The measurement process is achieved through repeated strokes of 19 11/16″ (500mm), making the system accurate and consistent. Cutting capacity at 90 degrees reaches up to 15 3/4″ (400mm) x 12 3/4″ (320mm) for flat materials and 12 3/4″ (320mm) for round stock.

The machine features automatic height adjustment sensors that bring the bow down to the material at high speed. Once the cut is complete, the hydraulic control system lifts the bow automatically. This entire cycle is governed by a mechanical switch to ensure operational safety. Angle locking is managed by a hydraulic brake system, which can be monitored and adjusted via a digital counter mounted on the main body.

Ideal for demanding operations across Canada and the US, the Fully Automatic CGH Mitre Twin Pillar Saw BMSO-325CGH NC follows Betamax’s rigorous safety standards. As with all Bekamak machines, the emphasis is on both operator safety and long-term machine durability. The Fully Automatic CGH Mitre Twin Pillar Saw BMSO-325CGH NC is a reliable and efficient solution for industrial metal cutting requiring precise mitre configurations.

Click here to see all twin pillar saws.