Description

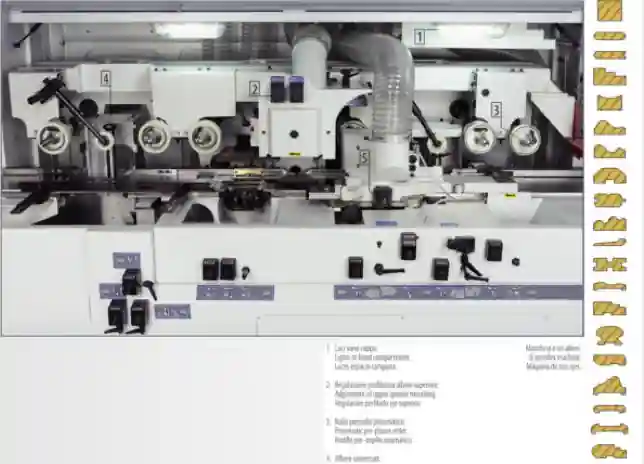

The Six Head Industrial Wood Moulder is a high-performance moulding machine that stands out from its smaller versions with its solid structure, working capacity, and standard and optional accessories. With six versions available, it is suitable for a wide range of machining requirements. The machine features vertical multi-tool spindles, allowing for four or more spindles to be used simultaneously for quick transition between jobs.

The horizontal upper spindle can accommodate cutters with a minimum diameter of 4.33″ and a maximum of 7.87″. The controls located in front of the hood have mechanical displays, allowing for precise control of horizontal and vertical spindle movements (1.57″).

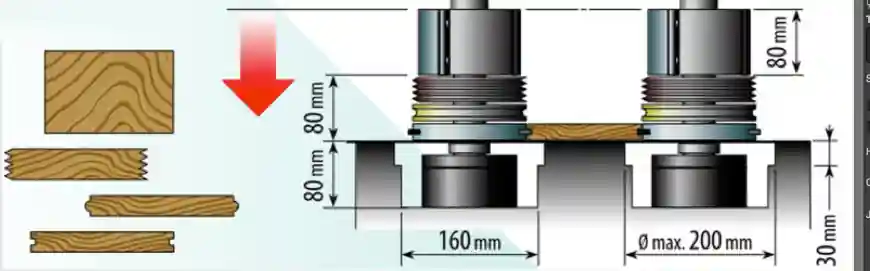

For certain operations, the tool may need to be lowered under the worktable. This is possible by removing the mobile shelf. The Six Head Industrial Wood Moulder also features a motorized rubber-coated roller under the worktable (standard) and an optional double roller under the table.

The vertical spindle can hold four or more cutters, allowing for quick and easy changeover between machining operations.”

Reshape your wood

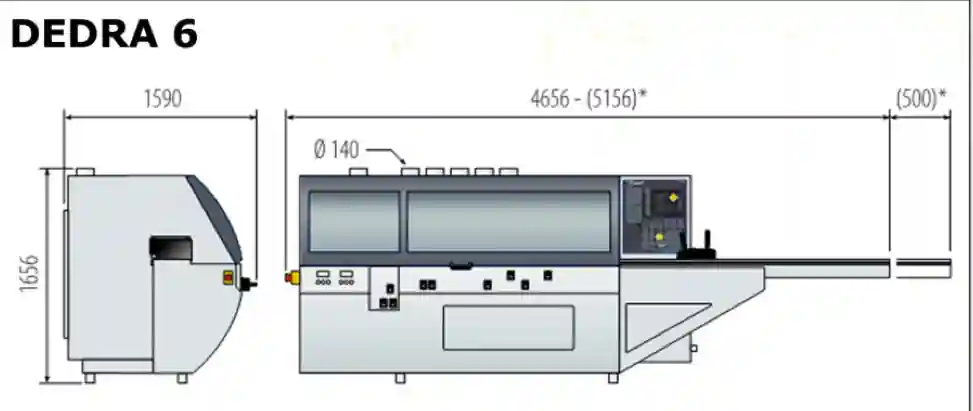

Automatic 6 spindles straightening, moulding machine. With its version with 6 spindles, Six Head Industrial Wood Moulder offers the possibility to satisfy the requirements of the small and medium sized industries. The rich standard equipment includes 90.55″. worktable, pneumatic pressure on drive rollers, motor start by direct push-button, pneumatic pre-planer roller, motorized lifting, roller drive with universal joints.

the technical features of the DEDRA machine include the possibility to fit shaped tools with diameter min. 4.33″ and max. 7.08″ on the right and left vertical spindle moulders and on the 4th horizontal spindle. the whole allowing working capacity with a high finish level.

TECHNICAL DATA

- Max working width: 9.45″

- Min working width: 63/64″

- Max working height: 5.11″

- Min working height: .27″

- Planer spindle motor power: 5,5 HP (4 Kw).

- Rh and Lh toupie motor power: 5 HP (4 Kw).

- Upper horizontal motor power: 7,5 HP (5,5 Kw).

- Feeding rollers speed: 4/20 m/min.

- Spindles rotation speed: 6000 rpm

- Toolholder spindle diam.: 1.57″

- Diam. and length of 1st horizontal spindle tool: 4.92-9.44 inches

- Diam. and height of vertical spindles head: 4.92-5,11″

OPTIONAL

- Automatic control of four axes (height / vertical travel of RH / LH spindle).

- 2-axis programmer with electronic management of working width and height, with possibility of holding 100 different recipes.

Six Head Industrial Wood Moulder usage

A Six Head Industrial Wood Moulder is a specialized machine used in the woodworking and furniture manufacturing industry. It is designed to shape and finish wooden materials with precision and accuracy. It is typically used for creating complex and detailed profiles, such as crown molding, baseboards, chair rails, and other decorative elements. It can also be used to create window and door frames, flooring, and other building materials. It is particularly useful for producing large quantities of identical parts, as it allows for quick changeover between different cutting tools. Additionally, it can also be used in millwork, cabinetry, and other woodworking applications where precision and efficiency are important.

Click here to see all Moulding banding machines.

Contact your sales representative to get your price for the four or five head moulder.