Description

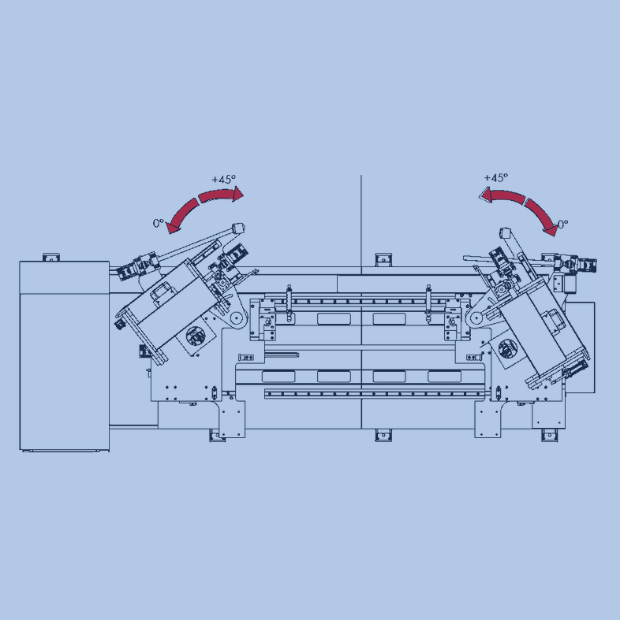

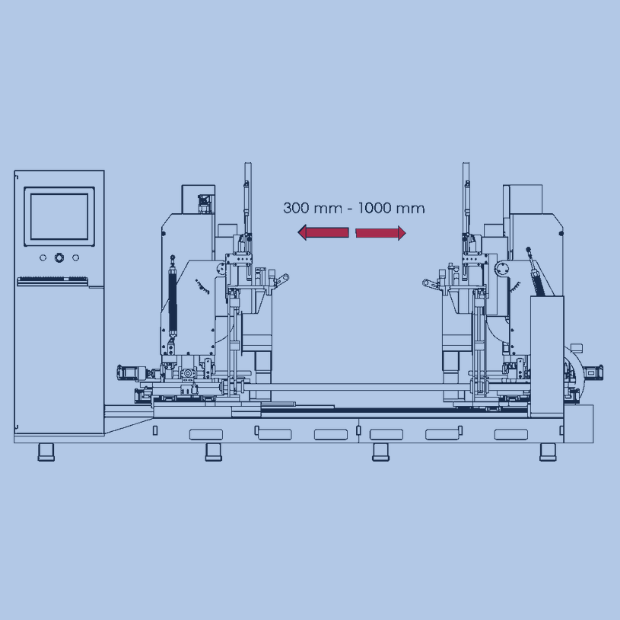

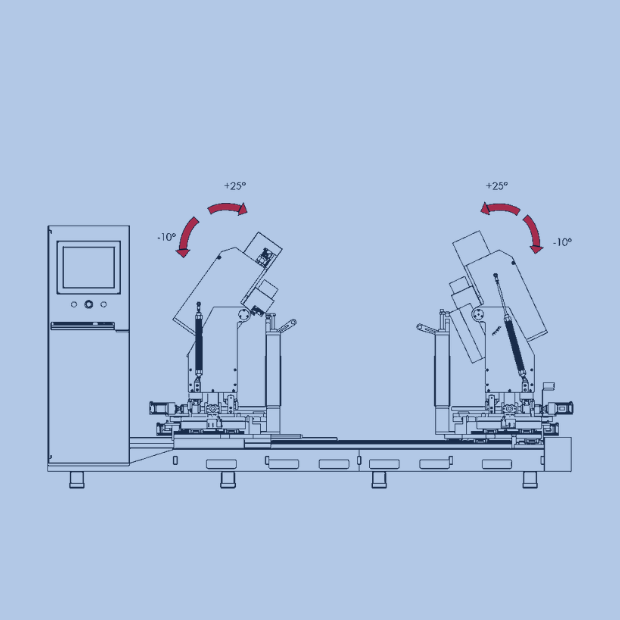

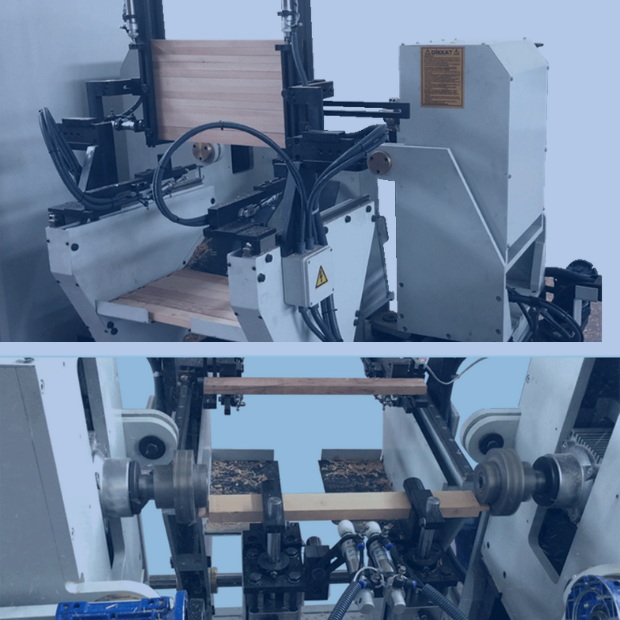

The CNC Double End Tenoner is an advanced woodworking solution designed for simultaneous processing of both ends of a workpiece. This powerful and efficient machine significantly reduces production time while ensuring absolute precision. During the tenoning process, pneumatic grippers securely hold the workpiece in place, preventing any unwanted movement or misalignment that could affect the quality of the cut.

An automatic feeding unit transports each piece safely to the processing centre. Once the operation is completed, the processed part is smoothly delivered in front of the operator, ready for inspection or the next step in the workflow. This seamless material handling not only increases productivity but also reduces manual labor.

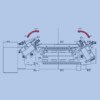

The CNC Double End Tenoner features specially developed MACRO software that allows users to program tenon dimensions parametrically and store them for future use. This makes it easy to handle both custom and repetitive production tasks with consistent quality.

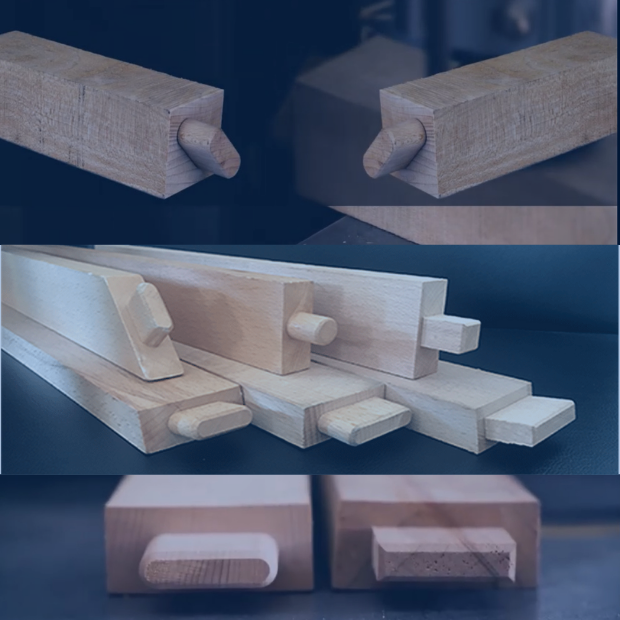

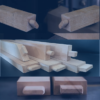

With the CNC Double End Tenoner, you can produce all kinds of tenon ends–including angular, round, angled, or even curved profiles. Its CNC-controlled system ensures precision across every cut, making it ideal for high-quality joinery and furniture manufacturing.

In any modern woodworking shop, the CNC Double End Tenoner is an essential tool for accuracy, efficiency, and versatility.

Click here to see all furniture working machines.