Description

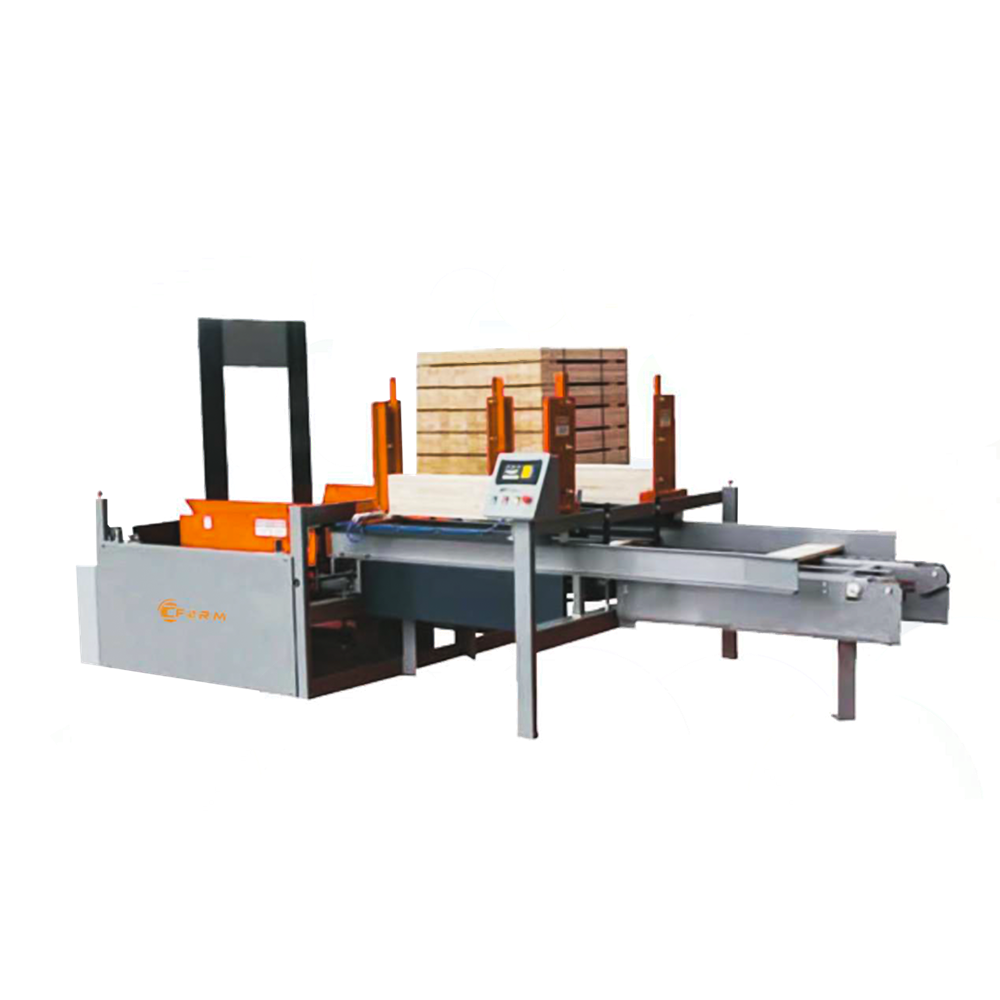

The Board Stacker Machine is engineered to streamline and optimize the stacking process in wood handling and pallet production environments. Designed with practical efficiency in mind, the Board Stacker Machine features an integrated entry band, a reliable separator clamp, a transversal conveyor, and a dependable exit conveyor to support smooth and continuous material flow during operation.

At the heart of the system is the stacker, which includes both a right charger (clip) and a left charger (clip). This dual-clip setup ensures consistent and accurate alignment of boards, regardless of production volume or pace. The separator ramp plays a key role in organizing boards before they enter the stacking phase, while the transversal conveyor ensures even distribution across the stacking platform.

Thanks to its modular configuration and clear operational layout, the Board Stacker Machine is both a user-friendly and highly functional. Each section–from entry to exit–is designed for robust performance and long-term durability. Whether you’re processing small batches or running continuous shifts, the Board Stacker Machine delivers consistent stacking results while minimizing manual handling and maximizing throughput.

With these core specifications, this machine is a practical solution for any wood processing facility looking to streamline stacking and improve production efficiency.

Click here to see all pallet machines.