Description

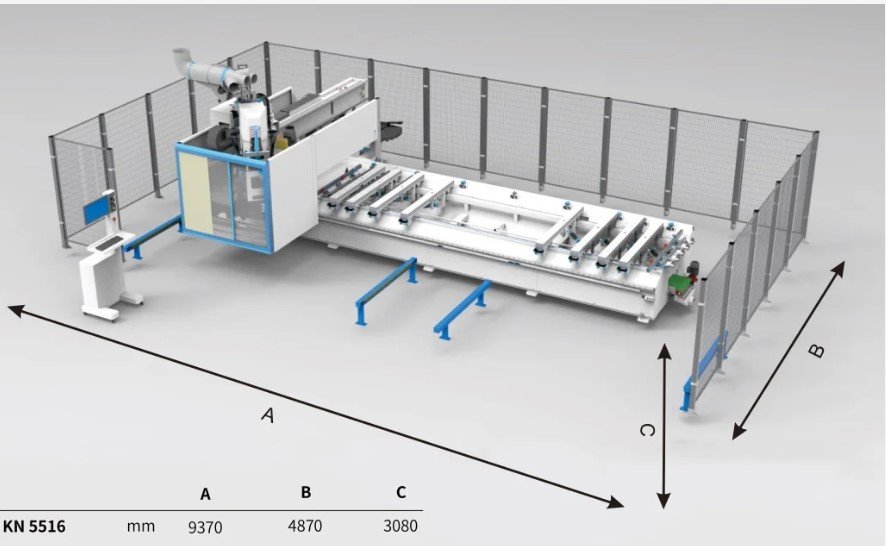

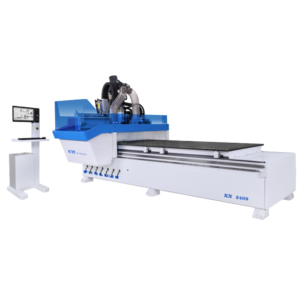

Pod and Rail CNC Router KN-5516 with five working axis is giving door and custom millworks the flexibility and accuracy they need for any type of milling, cutting and drilling on the 6 side of the product.

Pod and Rail CNC Router KN-5516 Key Features:

- Processing area 5150x1500x200 mm;

- Table type: Movable traverses “SCHMALZ”;

- Spindle: HSD (Italy) – 12 kW for HSK-63F chucks;

- Drilling and filler group: 12V+8H+1S;

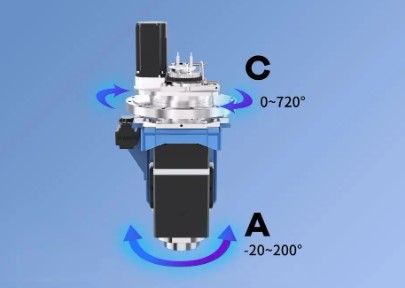

- 4th axis – C (0 – +720°);

- 5th axis – A (-20° – +200°);

- Servo motors for moving the gantry and spindle along the X/Y/Z axes: – 1/0.5/1 kW;

- Movement speed along the X/Y/Z axes: – 48/48/15 m/min;

- The mechanism of automatic tool change of revolving type for 22 tools + linear for 5 positions;

- Control rack OSAI (Italy) in Russian;

- The conveyor for removal of shaving installed in a basic complete set of the machine;

Pod and Rail CNC Router KN-5516 Technical Specifications:

-

Control system OSAI (Italy) Table size, mm 5150×1500 Spindle HSD, 12 kW, 24000 rpm, for HSK-63F clamp 4th axis C HSD (0 – +720°) 5th axis A HSD (-20° – +200°) drilling head 12 vertical + 8 horizontal spindles (4500 rpm) + 125 mm grooving saw (5400 rpm) Tool change revolving for 22 places + linear for 5 places Maximum tool diameter, mm 240 Maximum tool length (excluding workpiece height), mm 200 Moving speed A/C axes, °/s 40 Travel speed in X/Y/Z, m/min 48/48/15 Servo power in X/Y/Z, kW 1/0.5/1 Table configuration 8 vacuum traverses, SCHMALZ suction cups Total power consumption, kW 29,2 Productivity of vacuum pumps, m3/hour 1×244 Overall dimensions LxWxH, mm 7830x4365x3100 Weight, kg 5000