Description

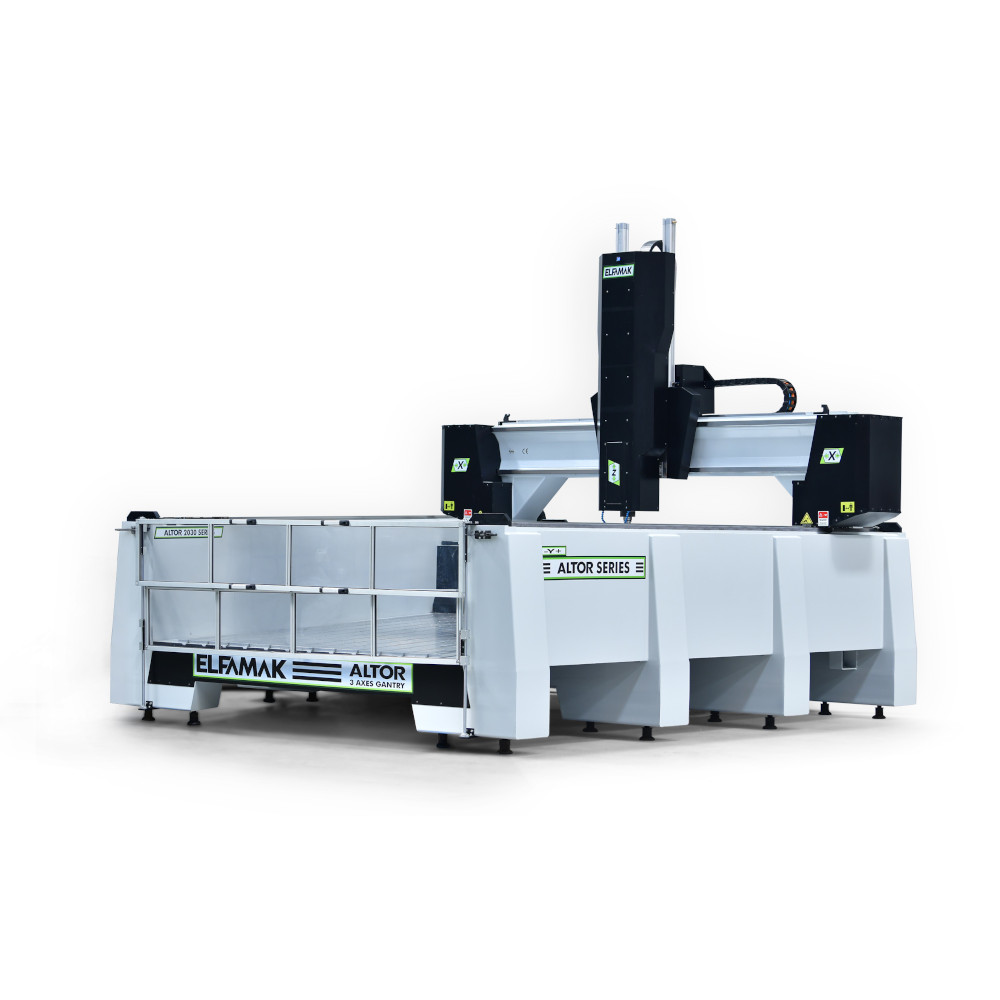

The Aluminum Panel and ACM and Alubond CNC Router is setting a new standard in the cladding industry by delivering exceptional performance, versatility, and precision. Designed to meet the evolving needs of modern fabrication, this router exceeds expectations with its integrated design and manufacturing software, allowing users to streamline the entire workflow from CAD design to production.

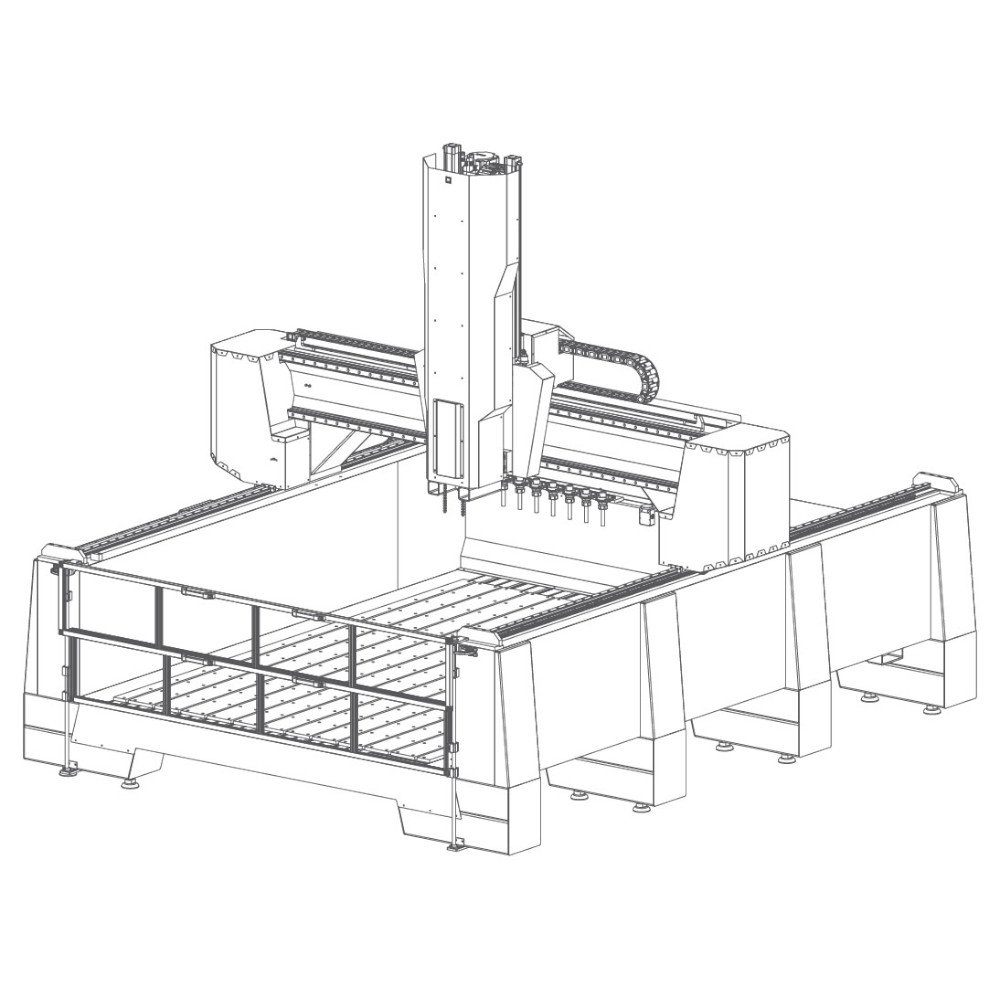

One of the standout features of the Aluminum Panel and ACM and Alubond CNC Router is its automatic label printer, which simplifies panel identification and improves organizational efficiency on job sites. At the heart of the machine is a powerful 12kW main spindle equipped with a 12-position automatic tool changer, allowing for rapid tool swaps and uninterrupted production. In addition, two supplementary spindles are included to handle secondary operations or simultaneous processes, further boosting productivity.

The standard working area of the Aluminum Panel and ACM and Alubond CNC Router is 5 feet by 12 feet, ideal for handling standard aluminum and composite panel sizes. However, for larger projects or high-volume operations, the machine can be customized in two-foot increments to accommodate cutting tables up to 40 feet in length.

Built with precision engineering and robust components, the Aluminum Panel and ACM and Alubond CNC Router is a trusted choice for cladding companies looking to improve accuracy, reduce labor, and optimize overall production efficiency.