Description

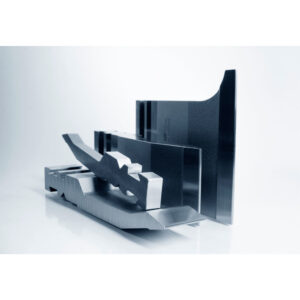

The BBM-25 Bordering Machine is specifically engineered for shaping and forming swaged plates, creating secure connections, and producing other critical components typically used in the fabrication of circular pipes. This process involves the precise deformation of thin metal plates into ribbed or contoured shapes, which serve both functional and structural purposes in various metalworking and fabrication industries.

By adding ribbing or contouring along the surface, the BBM-25 Bordering Machine significantly enhances the rigidity and structural integrity of plates, round pipes, or other metal components. This increased stiffness helps in reducing deformation and wear over time, making it particularly valuable in applications that require long-term durability and strength.

The BBM-25 Bordering Machine itself is built with a robust steel-welded frame, providing a solid foundation and long-lasting durability even under continuous use. It features an adjustable idle roller, giving operators greater flexibility and control during the forming process.

To ensure smooth, efficient performance, the BBM-25 Bordering Machine comes equipped with a precision steel shaft supported by bronze brushings. This setup allows for reduced friction and consistent motion. A reduction motor with an integrated tracking system provides stable and reliable operational control. Additionally, the roller movement is managed via a convenient foot pedal, freeing the operator’s hands for material handling.