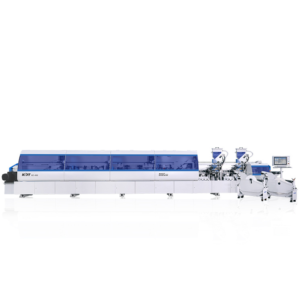

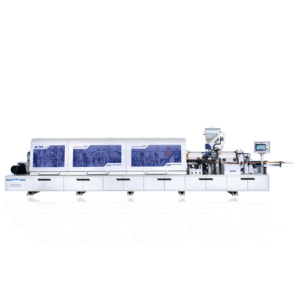

Elevating Woodworking with Edge Banding Machines

In the realm of woodworking, precision meets innovation through edge banding machines. These devices have transformed the process of affixing protective and decorative edges to wooden panels. Here’s why they’ve become a staple in workshops and factories:

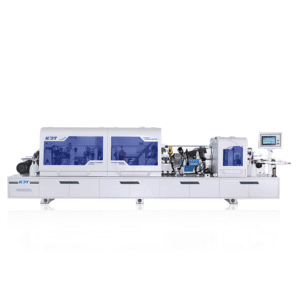

Efficiency and Precision: Edge banding machines excel in delivering consistent and flawless results. They automate the process, ensuring that edge bands adhere evenly and seamlessly. This precision not only saves time but also produces a professional finish.

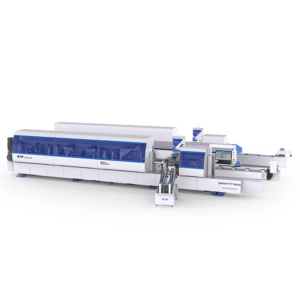

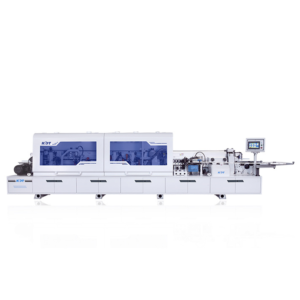

Time Saver: Traditional edge banding can be labor-intensive. Edge banding machines streamline the process, freeing up time for more projects. This efficiency enables craftsmen to meet deadlines and take on more work.

Enhanced Appearance: These machines elevate aesthetics by applying edge bands with unparalleled accuracy. The result is a refined appearance that adds to the overall allure of the final product.

Durability and Protection: Edge bands serve as protective barriers for vulnerable edges. Machines ensure a secure bond that guards against moisture, impacts, and wear, extending the lifespan of the product.

Adaptability: Modern machines accommodate various materials, sizes, and profiles. This versatility makes them suitable for different woodworking applications.

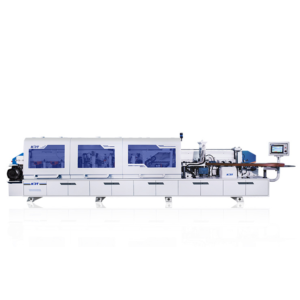

Waste Reduction: Precise application minimizes errors and wastage. Edge banding machines contribute to material and cost savings by reducing the need for rework.

User-Friendly: Designed with ease of use in mind, these machines feature intuitive controls and interfaces, catering to both seasoned woodworkers and beginners.

In summary, edge banding machines represent a marriage of technology and woodworking expertise. With their ability to deliver consistent, durable, and visually appealing results, these machines continue to shape the future of woodworking, one impeccable edge at a time.

Showing all 31 results