The integration of coil feeders with fiber laser tables introduces a powerful approach to metal fabrication. Let’s explore how this dynamic combination unlocks advantages that streamline your production processes.

Unmatched Efficiency lies at the heart of this system. With continuous production capabilities, coil feeders eliminate the downtime associated with manual sheet loading. Moreover, the automated nature of coil feeding reduces labor requirements and potential human error, further streamlining operations.

Enhanced precision and flexibility are hallmarks of coil-fed fiber laser systems. Fiber lasers offer superior cutting accuracy for consistently high-quality parts. Nesting software plays a crucial role, intelligently optimizing cutting patterns to minimize material waste. Plus, the ability to quickly adjust designs with software changes provides exceptional production flexibility.

Cost-effective production becomes a reality with coil feeders. The optimization of material usage and reduced manual work dramatically lower your scrap generation and overall operational costs. Faster production cycles enabled by continuous cutting lead to increased output, amplifying your cost-saving potential.

Beyond these core benefits, coil-fed fiber laser systems offer additional advantages. Lower maintenance requirements stem from the reliability of fiber laser technology, reducing downtime and expenses. Workplace safety gains from automation, as operators have less direct interaction with the cutting process. These systems demonstrate remarkable versatility in handling various sheet metal thicknesses and materials, opening up a wide range of applications.

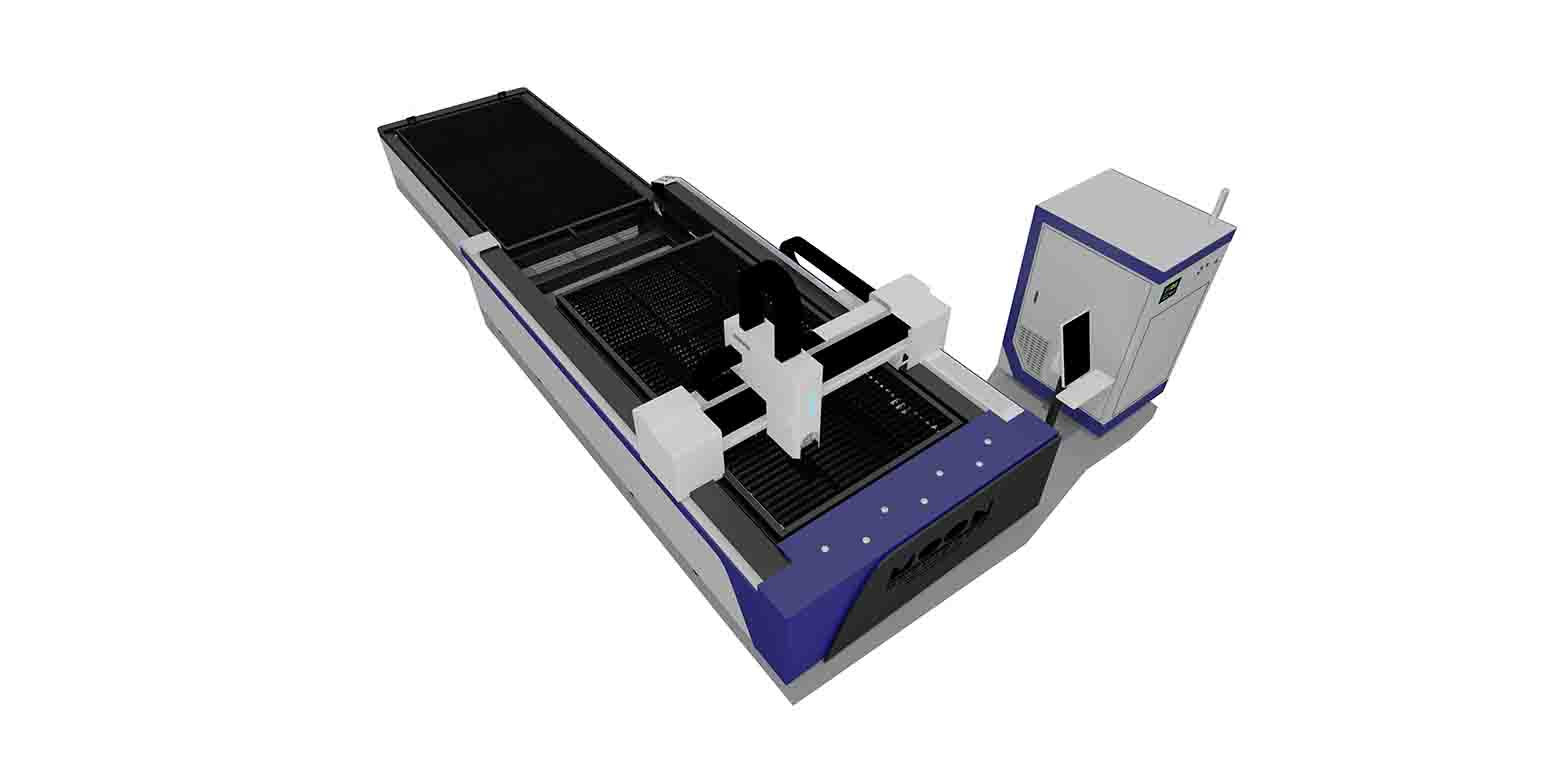

Coil Feeder Laser Machine Canada

In conclusion, the combination of coil feeders and fiber laser cutting tables delivers a powerful transformation within the metal fabrication industry. Through unmatched efficiency, superior precision, and significant cost savings, this technology paves the way for manufacturers to reach new heights of productivity and success.