Description

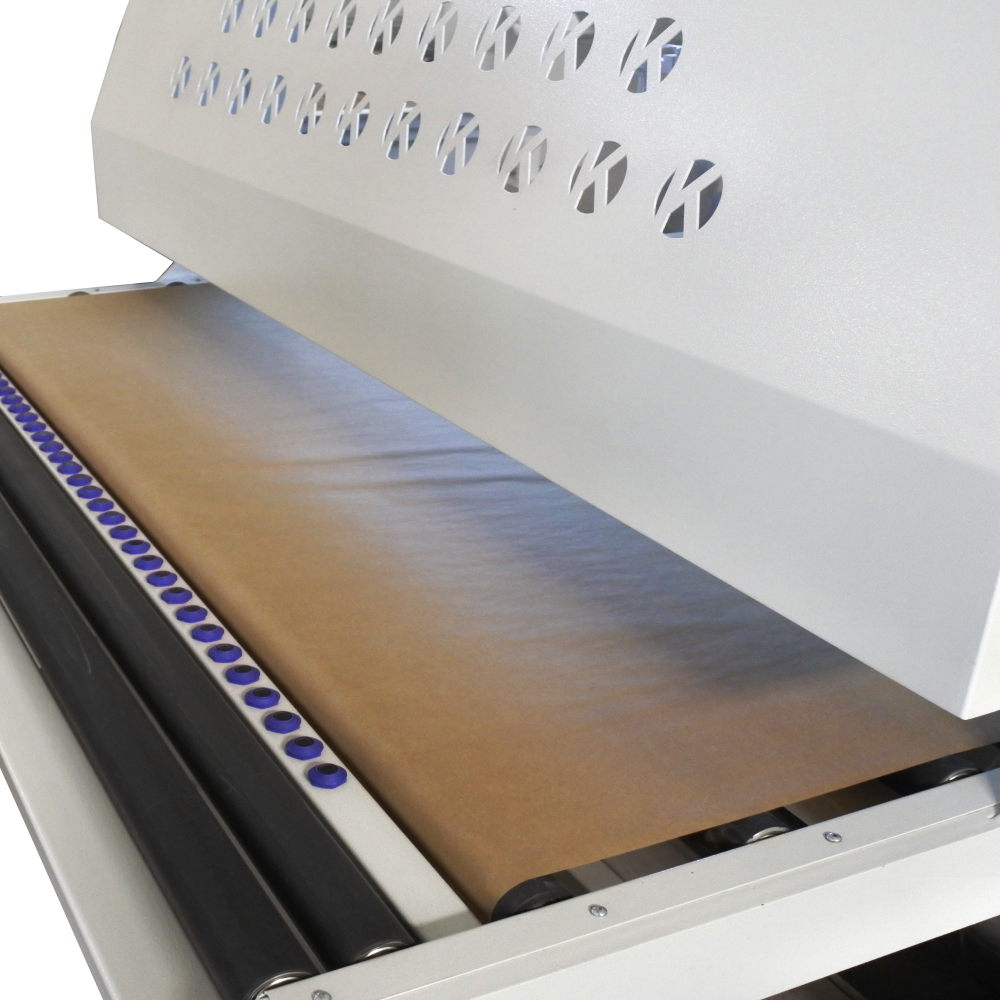

The Spray Machine KR BM 1000 K with paper roller has been designed and developed to provide the user convenience as well as obtaining a high quality machined surface of all kinds of panel materials. Our Automatic Spraying Machine provides fast painting of materials such as wood, glass, plastic, metal, fiber cement at low cost.

The Spray Machine KR BM 1000 K is a highly developed system. The painting process is done with a robot arm placed in the center and equipped with 4 high-pressure paint spray guns. The arm speed, which can be adjusted from the control panel, can be operated up to 590′ 6 5/8″ feet, 180 meters per minute if desired. Spray finishing machine can coat single pieces up to large batches with good quality and reliability. The Spray Machine KR BM 1000 K’s paint spray guns can be changed easily and angle and height can be adjusted thanks to its user-friendly design. The material to be sprayed is divided into microns and applied to the product at the right speed and pressure thanks to the high-pressure paint spray pump.

Where to use the Spray Machine KR BM 1000 K:

Wooden doors, door pulleys, door frames, modular furniture, kitchen and bathroom furniture, flat and carved cabinet doors, profiles, glass painting, glass coating, plastic, metal painting, fiber cement finishing machine.

Click here to see all coater, spraying machines.

canada, toronto, moon machinery, kama, karabudak machine, edge sanding machine, edge sander, spray coating machine, spray coater, oscillating system edge sander, drying systems, dry booths, furniture spraying, coating</p