Description

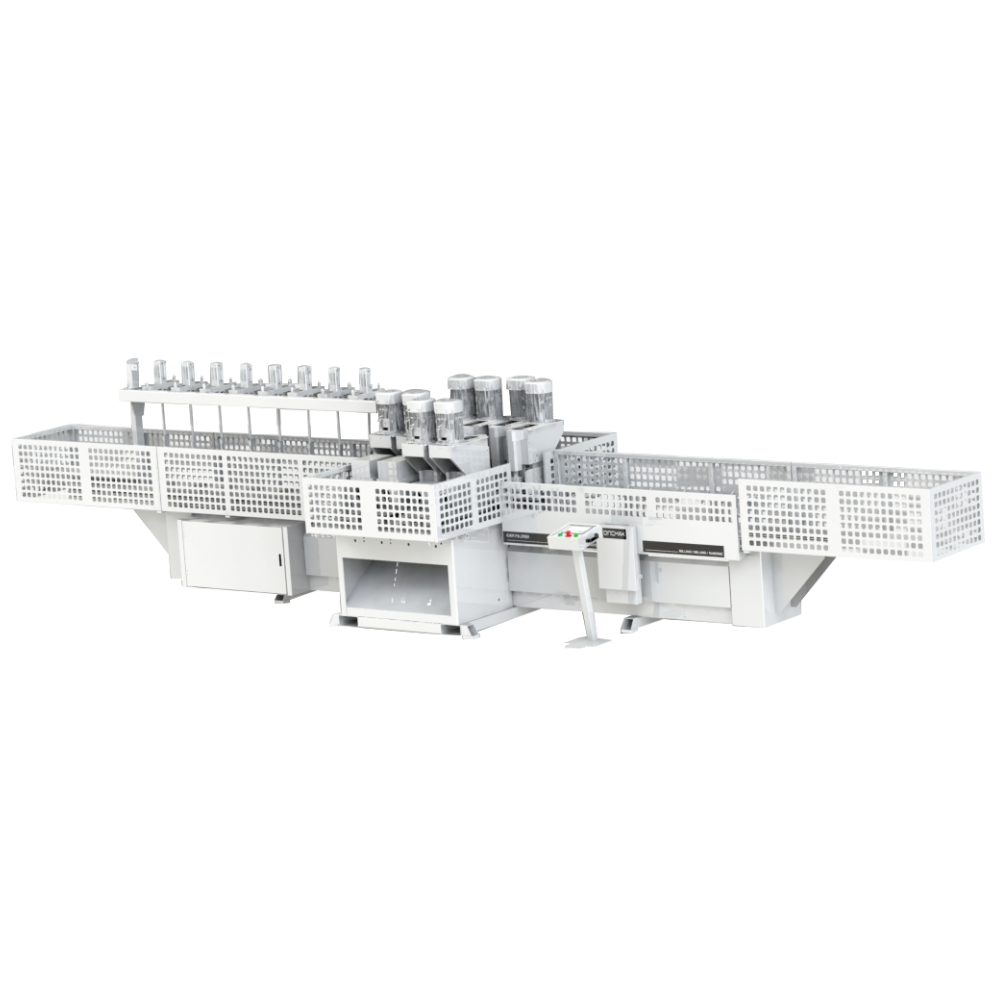

Double Side Linear Copy and Shaper;

For 2 Cutter:

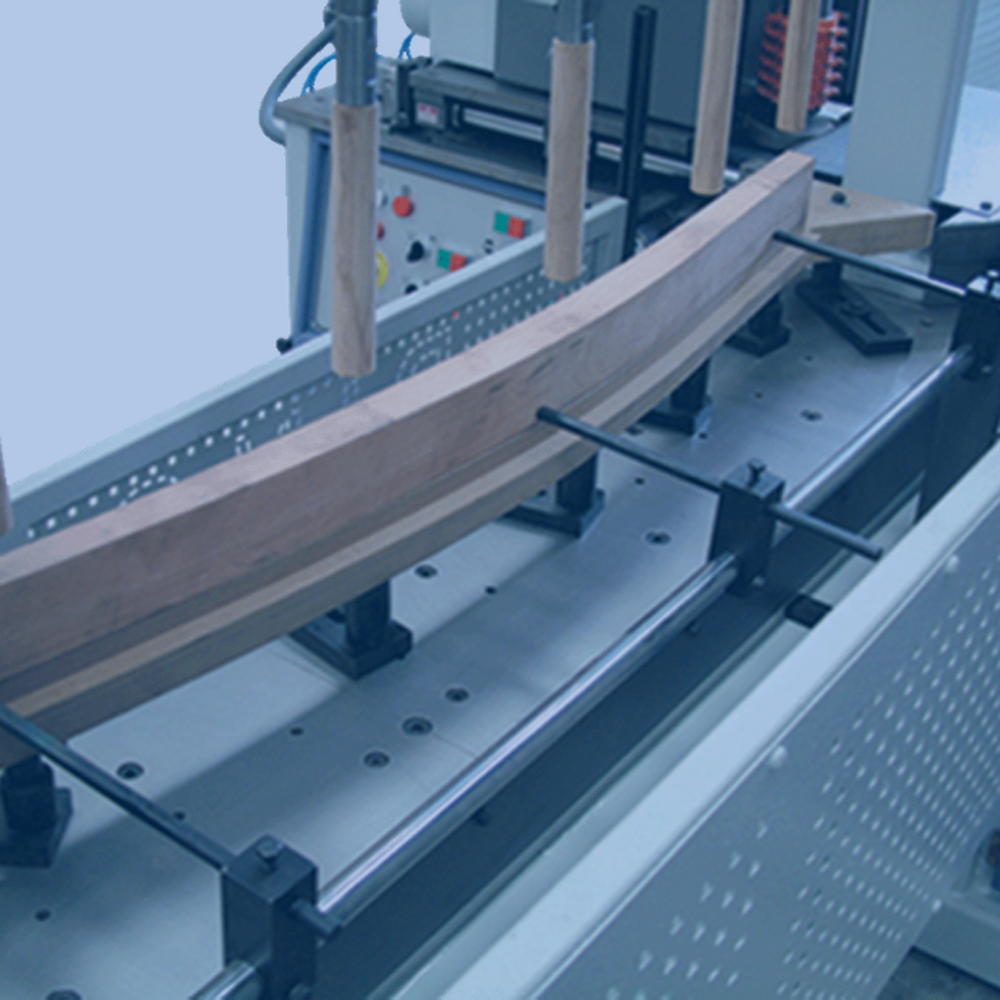

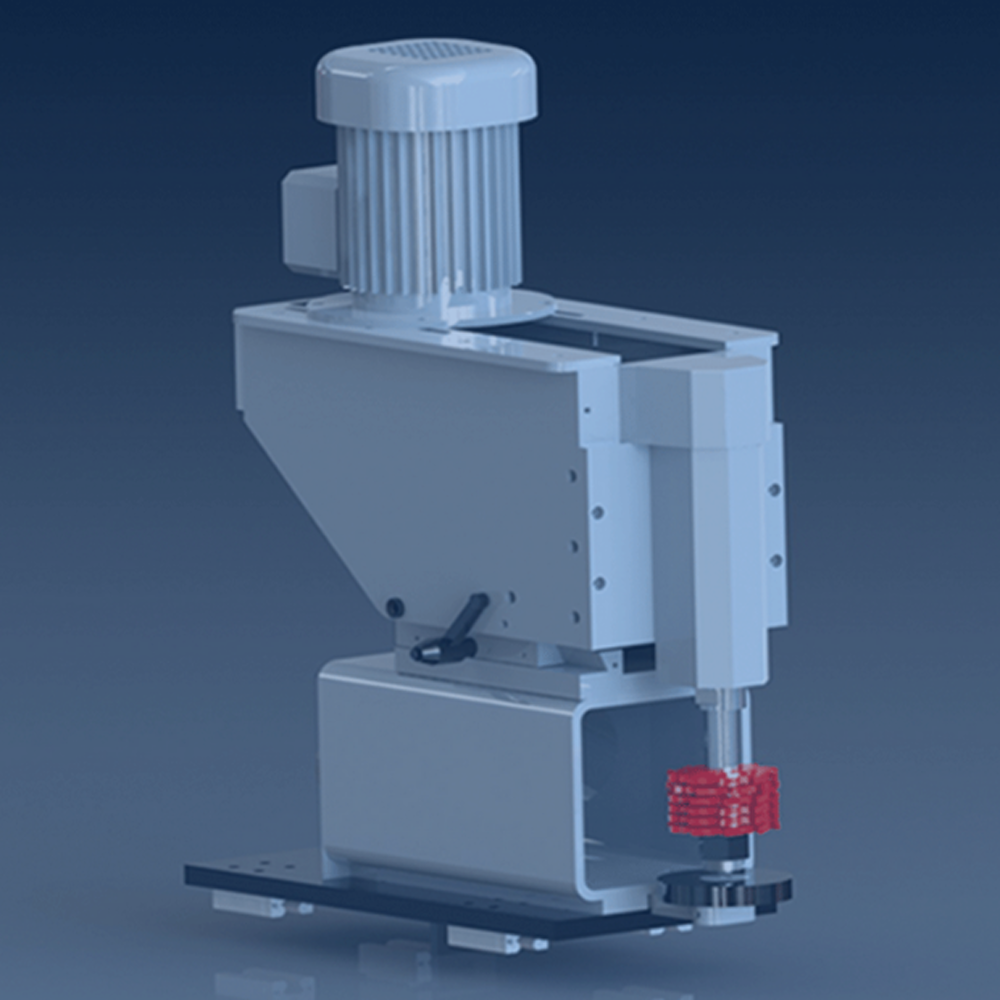

This Double Side Linear Copy and Shaper design includes 2 knives. There is a milling unit that is produced with a 5.5 kW motor and 150 mm, 5 7/8″ inch shaft as standard. Optional 7.5 kW motor and 180 mm, 7 1/16″ inch shaft option. The Double Side Linear Copy and Shaper is surrounded by helpful security barriers. The barrier in front of the operator automatically starts up when you start the operation. The compressing rods positions and tilts can be adjusted in accordance with the shape of the workpiece. This machines reference rods provide easy and accurate placement of the workpiece on the mold. The great design of the processing units that allows the shaft to be tilted backwards facilitates knive change.

For 2 Cutter 2 Sander:

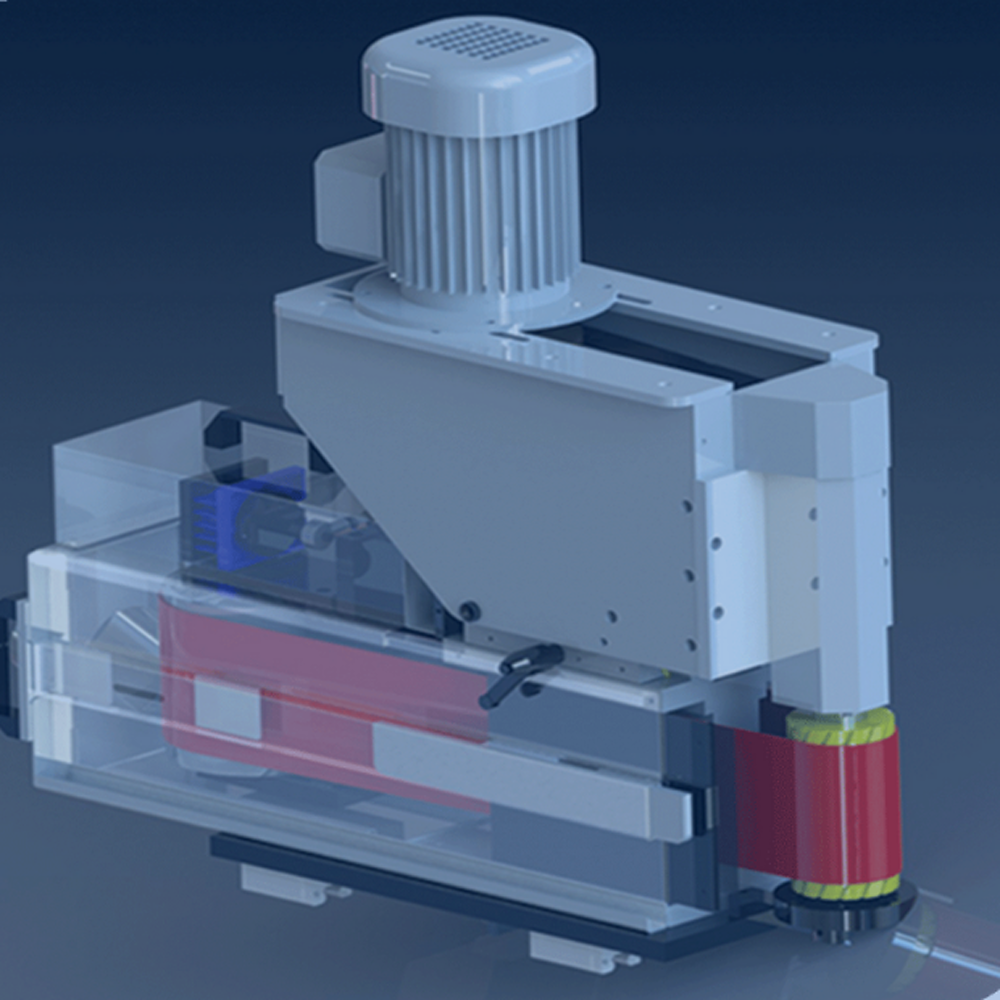

The better option from the 2 cutter is this Double Side Linear Copy and Shaper, it is designed with 2 knives and 2 sanders. This machine is equiped with a milling unit, it is produced with a 5.5 kW motor and 150 mm, 5 7/8″ inch shaft as standard. There is an optional 7.5 kW motor and 180 mm, 7 1/16″ inch shaft option (reccommended). Sanding Unit It is produced as standard with 4 kw / 3.2 kw double speed motor and 150 mm, 5 7/8″ inch shaft. If necessary, the sanding roller can be easily removed and used as a milling unit. 180 mm, 7 1/16″ inch shaft is an option. The machine is surrounded by security barriers to keep you safe. The barrier in front of the operator will automatically start up when you start the operation. The compressing rods positions and tilts can be adjusted in accordance with the shape of the workpiece. The machines reference rods provide easy and accurate placement of the workpiece on the mold. Brilliantly design of the processing units that allows the shaft to be tilted backwards facilitates knive change. Sanding belt’s down and up movement provide to sanding surface more clear and sensitive which is very helpful.

For 4 Cutter 2 Sander:

This Double Side Linear Copy and Shaper model is designed with 4 knives and 2 sanders. The milling unit is produced with 5.5 kW motor and 150 mm, 5 7/8″ inch shaft as standard. There is an optional 7.5 kW motor and 180 mm, 7 1/16″ inch shaft option that could highly increase your efficency (recommended). Sanding unit is produced as standard with 4 kw / 3.2 kw double speed motor and 150 mm, 5 7/8″ inch shaft. If necessary, the sanding roller can be removed and used as a milling unit. 180 mm, 7 1/16″ inch shaft is an option. The machine is surrounded by security barriers to keep you safe. The barrier in front of the operator is automatically start uo when you start the operation. The compressing rods positions and tilts can be adjusted in accordance with the shape of the workpiece for better acuracy. The reference rods provide easy and accurate placement of the workpiece on the mold that makes your life just a bit easier. The design of the processing units that allows the shaft to be tilted backwards facilitates knive change. Sanding belt’s down and up movement provide a sanding surface more clear and sensitive.

For 4 Cutter 4 Sander:

This is the most new, and best model designed with 4 knives and 4 sanders for most efficency. This Double Side Linear Copy and Shaper’s milling unit is produced with 5.5 kW motor and 150 mm, 5 7/8″ inch shaft as standard. Optionaly you could upgrade to an amazing 7.5 kW motor and 180 mm, 7 1/16″ inch shaft (most reccomended). The sanding unit is produced as standard with 4 kw / 3.2 kw double speed motor and 150 mm, 5 7/8″ inch shaft. If necessary, the sanding roller can be removed and used as a milling unit so you can always change your mind about the sanders. 180 mm, 7 1/16″ inch shaft is an option (highly reccommended). The Double Side Linear Copy and Shaper is surrounded by security barriers for high safty. The barrier in front of the operator is automatically starts up when you start the operation. The compressing rods positions and tilts can be adjusted in accordance with the shape of the workpiece for a better product. The reference rods provide easy and accurate placement of the workpiece on the mold to help you daily. The design of the processing units that allows the shaft to be tilted backwards facilitates knive change. This Double Side Linear Copy and Shaper’s sanding belt’s down and up movement provide to sanding surface to be more clear and sensitive.

Click here to see all of our spectacular furniture working machines.